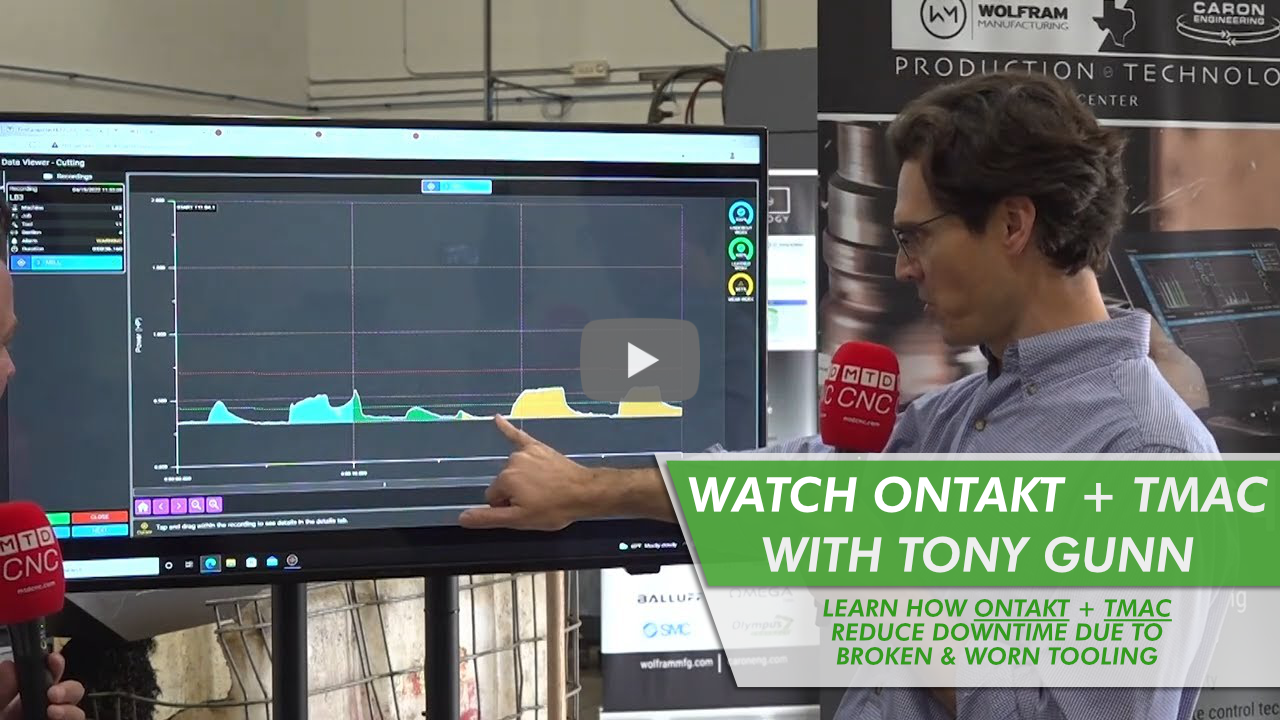

Tony Gunn talks OnTakt with TMAC Integration

Watch what happens when a tool wears out and TMAC from Caron Engineering stops the machine to notify an operator to perform a tool change. Our OnTakt software integrates directly with TMAC and can notify operators, shop floor supervisors, management, manufacturing engineers or anyone at your shop that a machine needs attention. With direct integration to Slack and Microsoft Teams your shop floor can stay on top of problems as the arrive. OnTakt can also predict when planned tool changes are happening, before they happen. Learn more as we discuss OnTakt with Tony Gunn.

CLICK TO WATCH HOW ONTAKT AND TMAC WORK TOGETHER

Do you want to see how TMAC and OnTakt can help your shop increase productivity with fewer operators? The Production Technology Center is a centralized hub for customers and potential users of Caron Engineering and Wolfram Manufacturing Technologies to access the latest solutions for CNC machine monitoring, automation, cycle time reduction, unmanned operation, and total process monitoring and control.

Our doors are wide open! Schedule a visit to see IN-PERSON how digital technologies from Caron Engineering, Wolfram Manufacturing Technologies, and other partners have resulted in 24/7 production with little to no machine operator intervention or attendance.

What happened here?

- TMAC stops a machine due to a wear alarm

- Machine alarms are integrated into our OnTakt software

- OnTakt sends out a notication thru Slack and Teams to notify operators that a machine stops

- Operator can go attend to a machine

What’s the end result?

- TMAC prevented a broken tool and scrapped part

- TMAC enables less operators to run more machines

- OnTakt notifies an operator when a machine needs help

- OnTakt predicts tool changes to minimize machine stoppages