Manufacturing for the Future

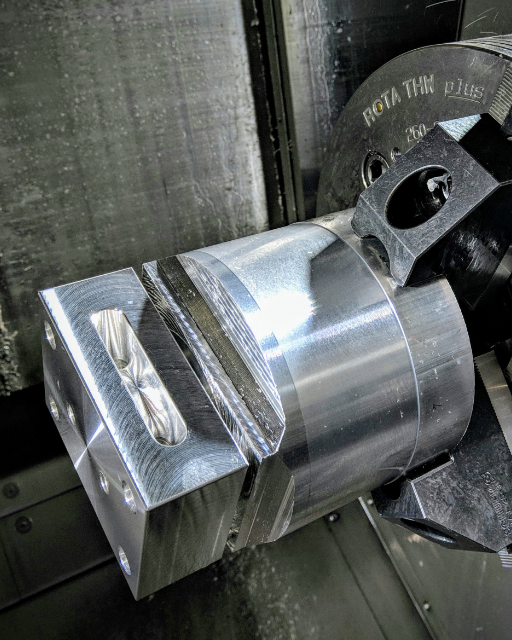

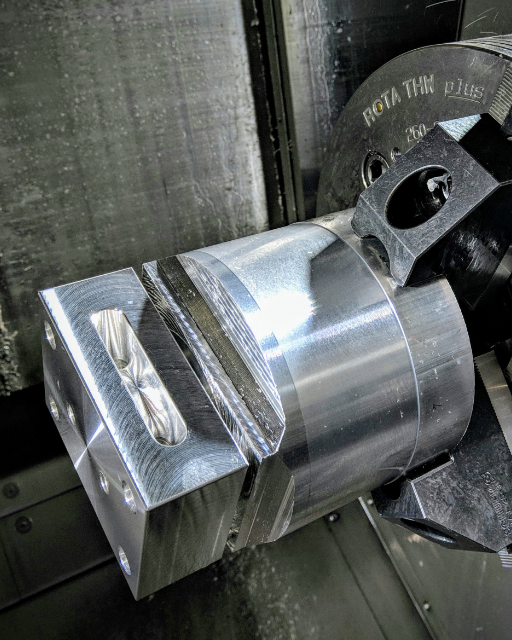

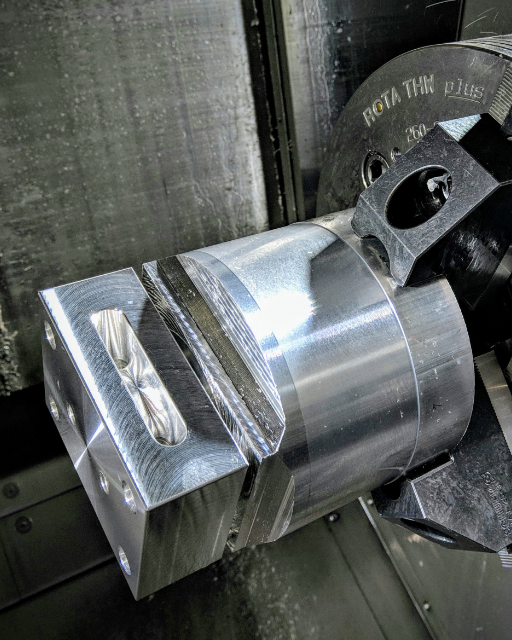

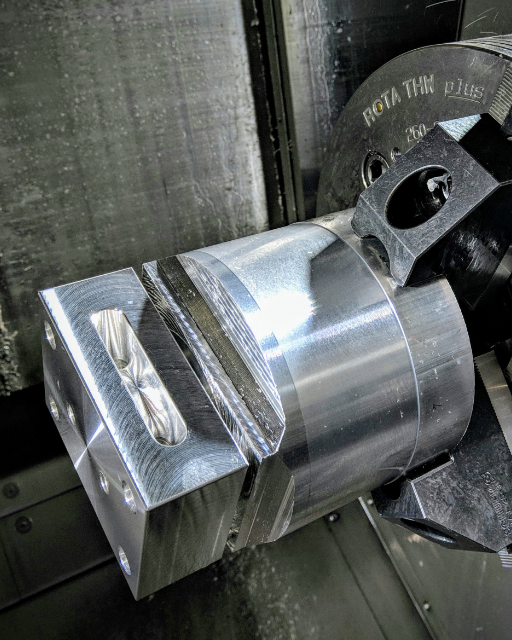

Wolfram Manufacturing runs what is best described as a production technology lab, which is both a working machine shop and a technology consulting firm helping OEM’s with tools like adaptive machining. Wolfram Manufacturing, at its founding in 2011, was an extremely versatile machine shop that specialized in medium to high volume production of metal parts. Wolfram focused on using the best technology manufacturing had to offer and appealing to the next generation of makers. Still operating a full production shop, Wolfram has expanded to offer consulting, training, and distribution of 3rd party hardware + software solutions to help their customers reach the next level. Wolfram Manufacturing exists as a place where ideas, innovation, and practical application come together to make the manufacturing world better.

Our Core Values

- Safety – Maintaining a clean and safe environment for both employees and customers.

- Integrity – Honoring our agreements and being loyal to partners.

- Accuracy – Accuracy in quoting, manufacturing, and record keeping.

- Innovation – Striving for continuous improvement in every aspect of our business.

Meet Our Team

Nathan Byman

President

Katherine Satterwhite

Director of Human Resources

Tim Urano

Quality and Process Manager

Lars Remsen

Engineering Manager

Chris Swaim

Director of Strategic Initiatives

Josh Blackwell

Director of Operations

Andrew Aguilar

Technical Product Manager

Manuel Schafer

Senior Sales Manager

Andy Castille

Software Architect

Kirby Martinez

OnTakt Product Manager

Aaron Davis

Senior Software Engineer

Jenna Roe

Executive Assistant

Ben Karrasch

Manufacturing Consultant

Alyssa Byrd

Production Manager

Eli Taylor

Engineer

Jordan Capola

Engineering Technician

Ryan Machus

Manufacturing Technician

Harley Pruett

Manufacturing Supervisor

James Hush

Senior Manufacturing Specialist

Chiron Mancini

Senior Manufacturing Specialist

Brittany Parette

Manufacturing Specialist, Shipping Coordinator

Stephen Janus

Lead Manufacturing Specialist

Nic Stasolla

Lead Manufacturing Specialist

Dale Ekdahl

Manufacturing Specialist

Adam Bedell

Manufacturing Specialist

Zach Smith

Manufacturing Assistant

Jude Colborn

Manufacturing Assistant

Storm Sarracino

Manufacturing Assistant

Chris King

Manufacturing Assistant

Travis Lynch

Manufacturing Technician

Jahquell Blan

Manufacturing Assistant

Quintin Hatt

Manufacturing Assistant

Jeff Davis

Special Projects

Olive

Chief Cuddles Officer

We’re Hiring

Join the Wolfpack!

OUR MISSION

Wolfram’s mission is to share our vision with the manufacturing industry. Wolfram focuses on developing and integrating manufacturing technologies in a visionary machine shop to create robust processes that make manufacturing safe, reliable, and competitive.

Wolfram distributes and integrates smart manufacturing solutions from Caron Engineering that reduce cycle times, promote unattended operation, reduce tooling costs, and minimize damage.

Wolfram started as a versatile machine shop that specializes in medium to high volume production. We continue to implement the newest manufacturing technologies in our own shop, everyday.

Wolfram develops software to extract data from your equipment and to make real-time decisions to make your shop as productive and profitable as possible.

OUR UNIQUE PROCESS

Although we price projects on a case by case basis, this is a guide to the services and project packages we offer to our clients.

ADAPTIVE MACHINING TOOLS

We distribute, support, and provide applications for the tools needed to allow your process to adapt to variations in real time. These adaptions are based on dimensions, tool wear in cut, or unexpected events. We support the whole line of Caron Engineering products which are the most advanced and highest performing in this field.