Case Studies

Find out how other shops are finding success with a wide variety of advanced CNC machine monitoring technologies that help solve unique manufacturing challenges. Download these case studies to learn how CNC machine monitoring and production management solutions from Wolfram Manufacturing Technologies reduce production costs and pay for themselves month in and month out.

Save $1,400 tracking variables with OnTakt

Tracking historical data part by part can drive continuous improvement at your shop

OnTakt has the ability to track macro or common variables in your CNC machines. In this video we show you how you can look at historical data captured in OnTakt to drive continuous improvement at your shop…

Real-Time Notifications Reduce Machine Downtime

OnTakt Provides Both Preemptive and Instant Notifications Based on the Status of Machines and Tooling.

When a machine stops unexpectedly, downtime usually occurs because the operator is busy with other tasks or doesn’t know the machine has stopped. OnTakt’s integration with Microsoft Teams and Slack allows your team to receive real-time notifications…

Use Data to Prevent Unexpected Machine Stoppages

Group Tool Changes to Minimize Downtime

When a machine stops for a routine tool change most of the downtime is spent waiting for an operator to begin the tool change. By grouping tool changes together for tools that will expire in the near future, downtime can be reduced….

Reduce Operator / Employee Costs

Enable “drop-in” shifts where operators can predict tool changes and prevent machine stoppages on unattended shifts

A shop can adopt “drop-in” shifts once it’s possible to predict an upcoming tool change. Leveraging TMAC from Caron Engineering gives our shop the confidence to run our machines unattended by significantly reducing the risk of damage from broken tools to parts or machines.

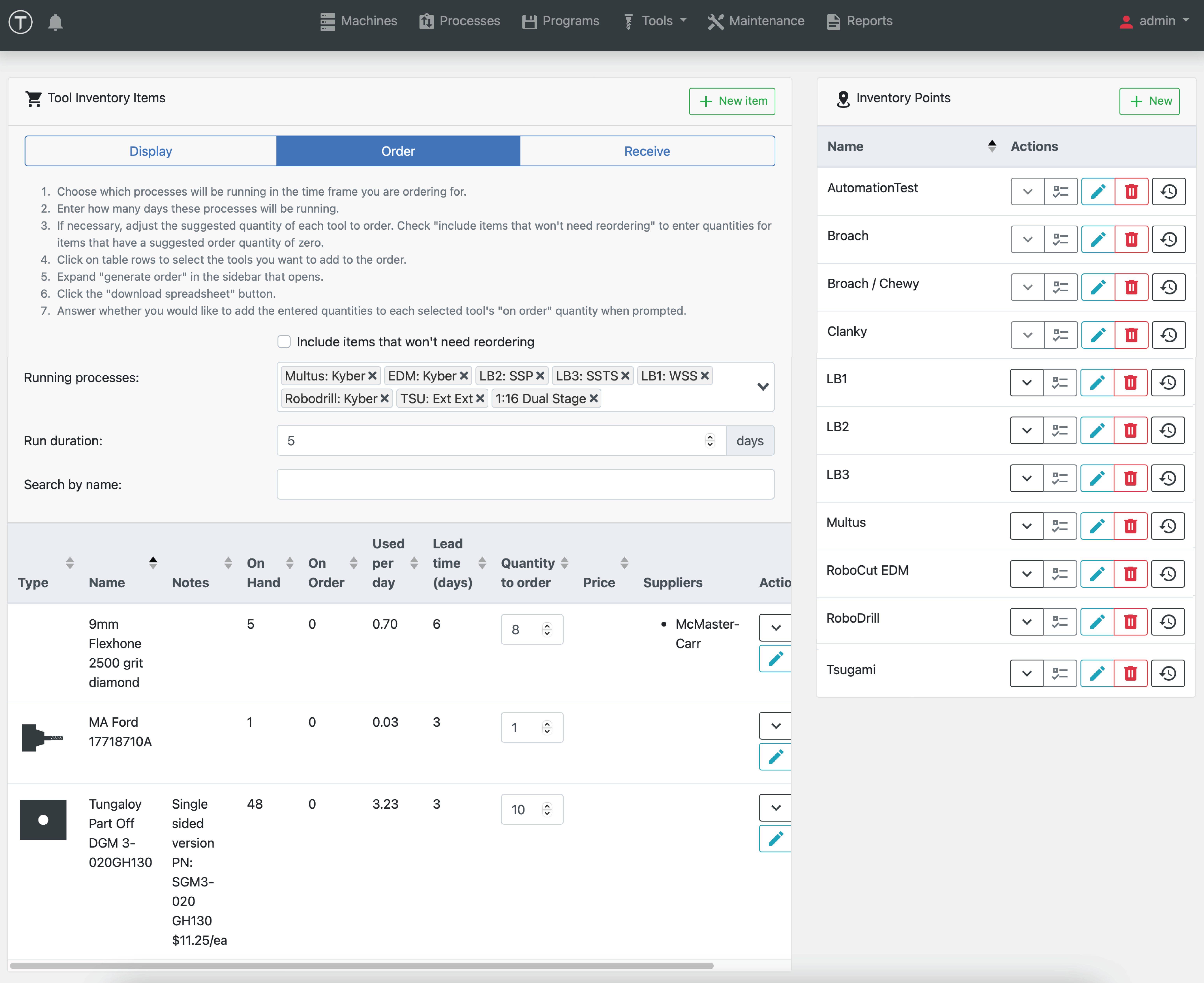

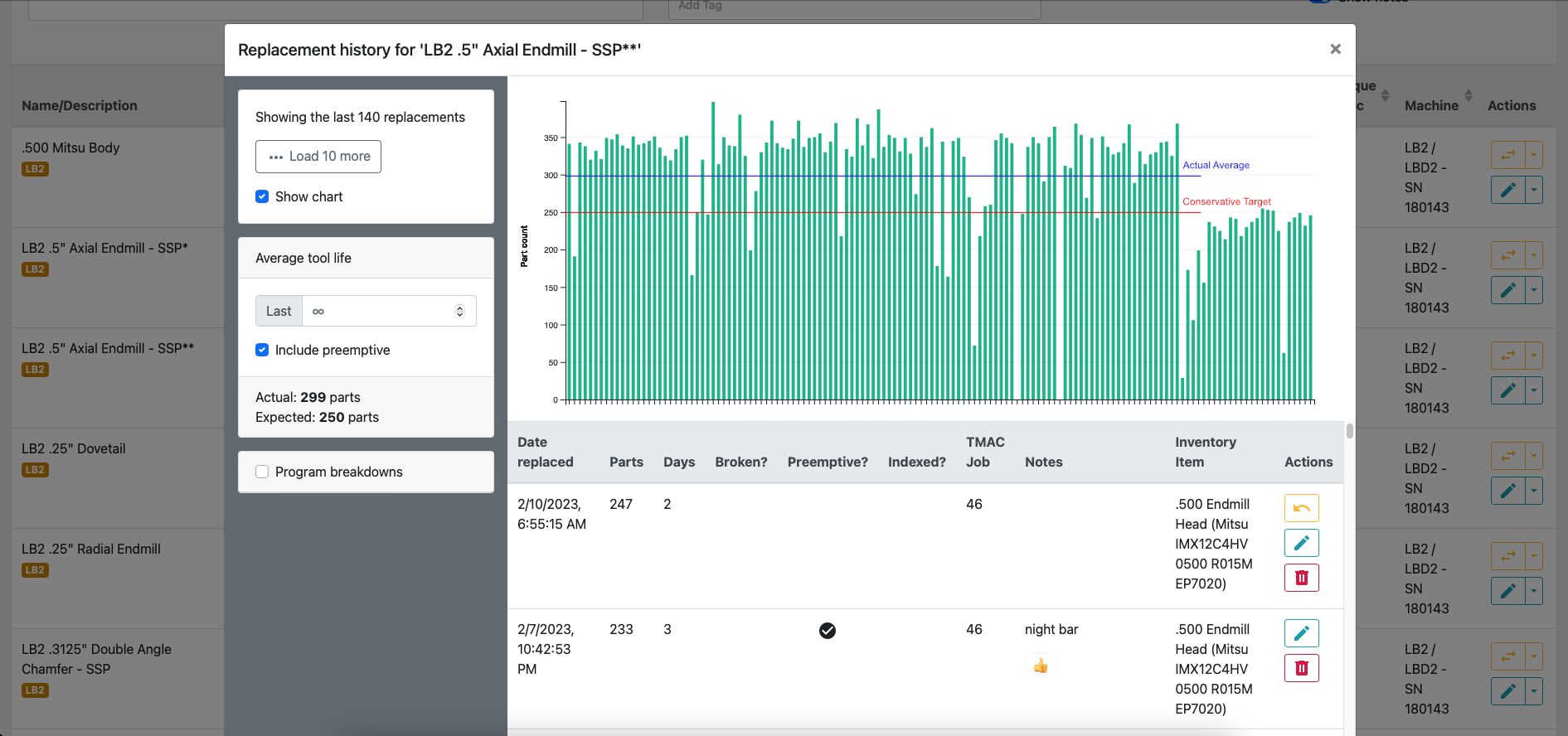

Reduce Tooling Costs

Identify a new tool or lot of tools that cause production problems

Every month, OnTakt will easily pay for itself by identifying the tools causing production problems. By monitoring the OnTakt tooling module, an operator can quickly assess when consumable and durable tools are underperforming or provide better-than-expected tool life…

Increase Production Efficiency with Historical Production Data

Use OnTakt to Identify and Justify Automation

OnTakt’s real-time data increases your shop’s productivity by reducing machine downtime. Capturing your production data over time also allows you to review historical performance and highlight opportunities to add additional automation or equipment to get more out of your existing machines…

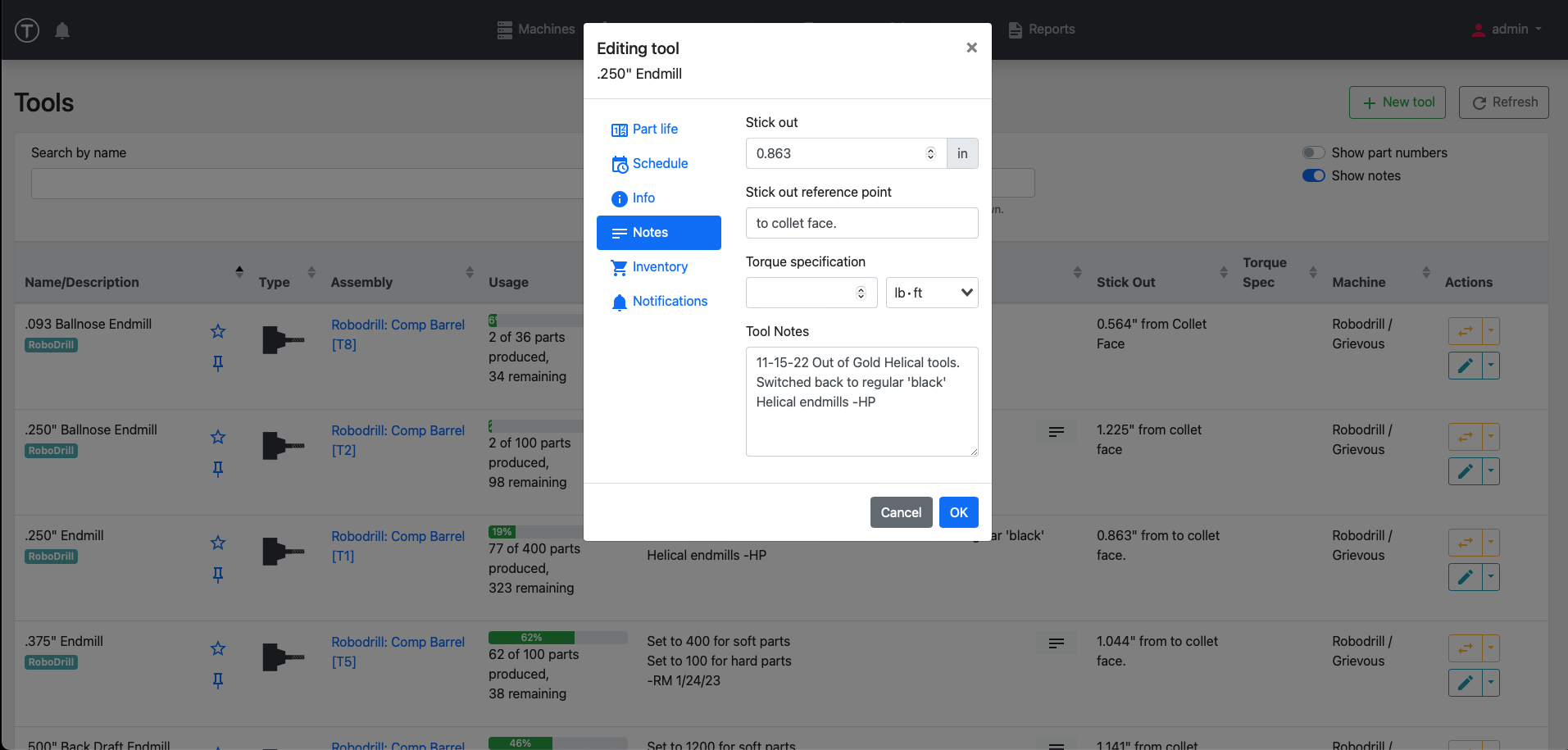

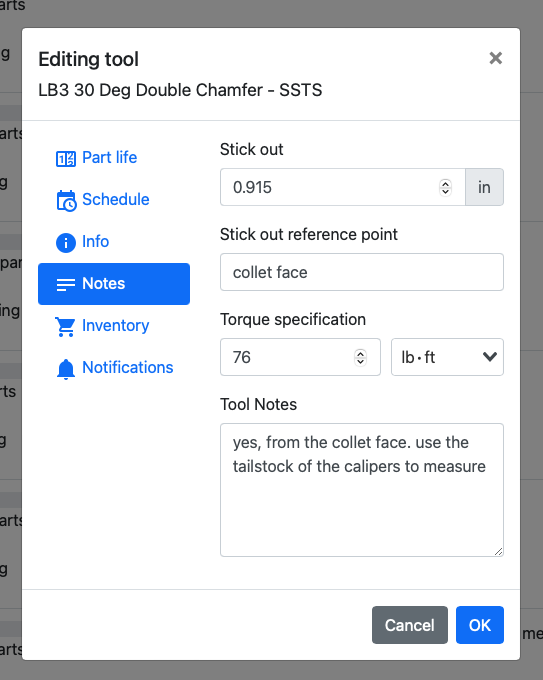

Track Important Process Information and Eliminate Paper on the Shop Floor

Ensure that information doesn’t get lost, misplaced, or misinterpreted

OnTakt is built to help your team capture in-process information to keep operations running smoothly. Enabling operators to add contextual information to tool changes, machine stoppages, scrapped parts, and more helps retain knowledge across an organization and minimize errors and downtime in the future…

Capturing Tribal Knowledge Can Level Up Your Organization

How much information do you lose when a highly skilled operator leaves? Can you put a value on “Tribal Knowledge?” OnTakt is designed to capture important contextual data from operators, shop supervisors, and engineers and to make it easily accessible throughout the shop and office. Download the case study to learn how OnTakt pays for itself every month, on every machine, by capturing tribal knowledge…

Visualize Data to Triage and Solve Production Problems Quickly

OnTakt tracks macro variables used on the CNC control in production programs. Because OnTakt captures macro variables and visualizes data over time, it becomes easy to troubleshoot production issues and identify process trends…

DOWNLOAD CARON ENGINEERING CASE STUDIES

Find out how other manufacturers are finding success with smart manufacturing solutions from Caron Engineering.

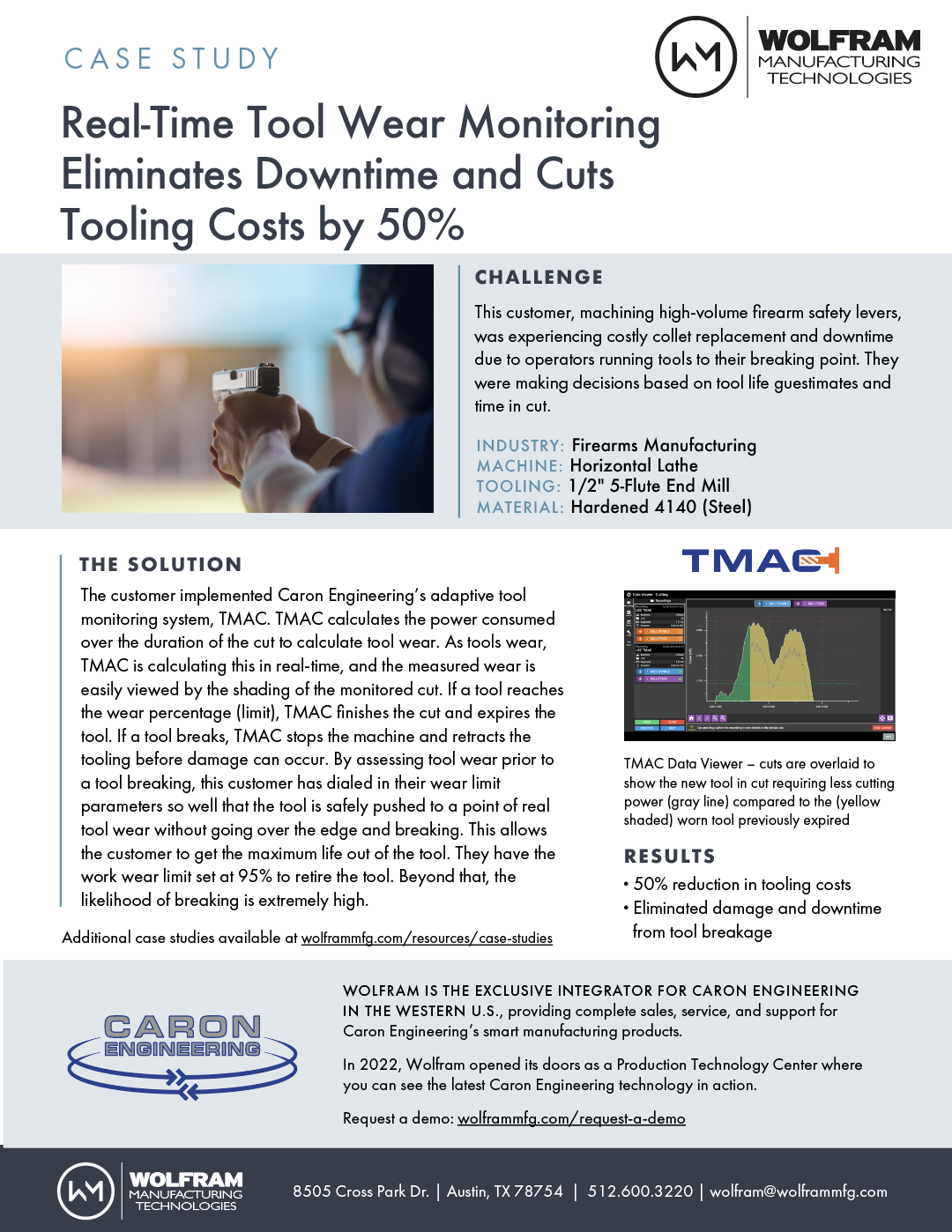

TMAC Cuts Tooling Costs by 50% for Firearm Manufacturer

Download the TMAC Case Study that shows how a firearm manufacturer reduced tooling costs and machine downtime on high-volume safety levers.

TMAC saves $5000 per month per machine on consumable tooling

Download the TMAC Case Study to learn more about how we save money at Wolfram Manufacturing with longer tool life through TMAC from Caron Engineering.

TMAC Saves $300K for this Automotive Customer Machining Camshafts

Download the TMAC Case Study to learn how a camshaft manufacturer used TMAC from Caron Engineering to detect if a critical hole was being machined, resulting in eliminating a downstream inspection.

TMAC eliminates scrap of $150k parts

Download the TMAC Case Study to learn how an aerospace manufacturer eliminates scrap of expensive parts with 100+ holes on an engine case.

TMAC Reduces Cycle time by 15% – 26%

Download the TMAC Case Study to learn how an aerospace manufacturer enabled 24/7 lights our production across 5 Okuma machining centers to reduce cycle time by 15% – 26%

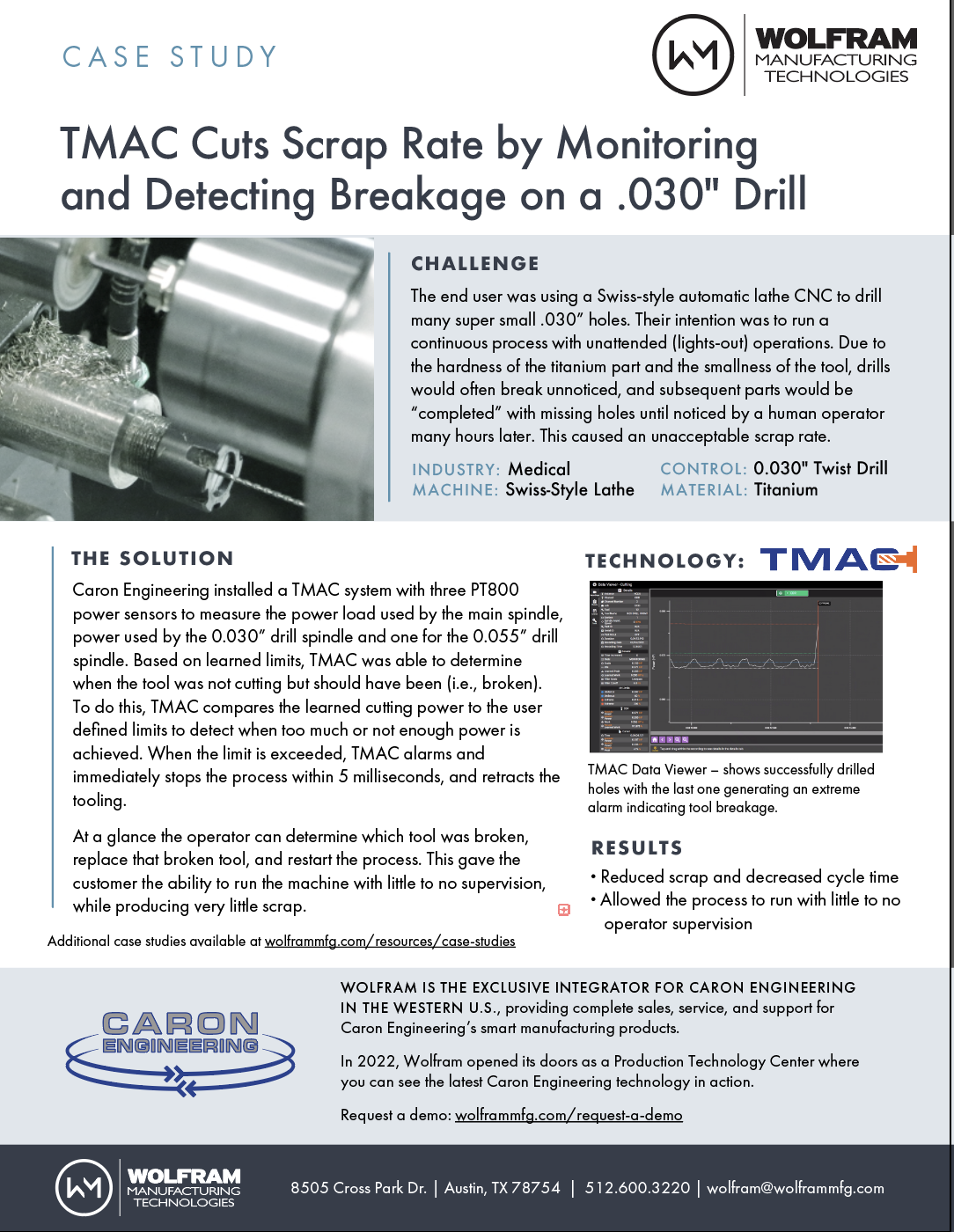

TMAC Detects Broken 0.030″ Drills

Download the TMAC Case Study to learn how a medical manufacturer used TMAC to monitor when small 0.030″ drills break unexpectedly on a Swiss-style lathe.

TMAC Immediately Stops Machine to Avoid Costly Crash

Download the TMAC Case Study to learn how an oil and gas manufacturer avoided a costly, catastrophic machine crash due to a robot incorrectly loading a component in the machine. TMAC stopped the machine before the second insert even contacted the part.

TMAC Cuts Cycle Time by 41%

Download the TMAC Case Study to learn how a customer reduced cycle time by 41% machining graphite iron engine block components on a Mazak Horizontal Machining Center by leveraging TMAC Adaptive Control.

ToolConnect Case Study

Download the ToolConnect Case Study to learn how to eliminate costly operator data-entry errors every shop encounters.

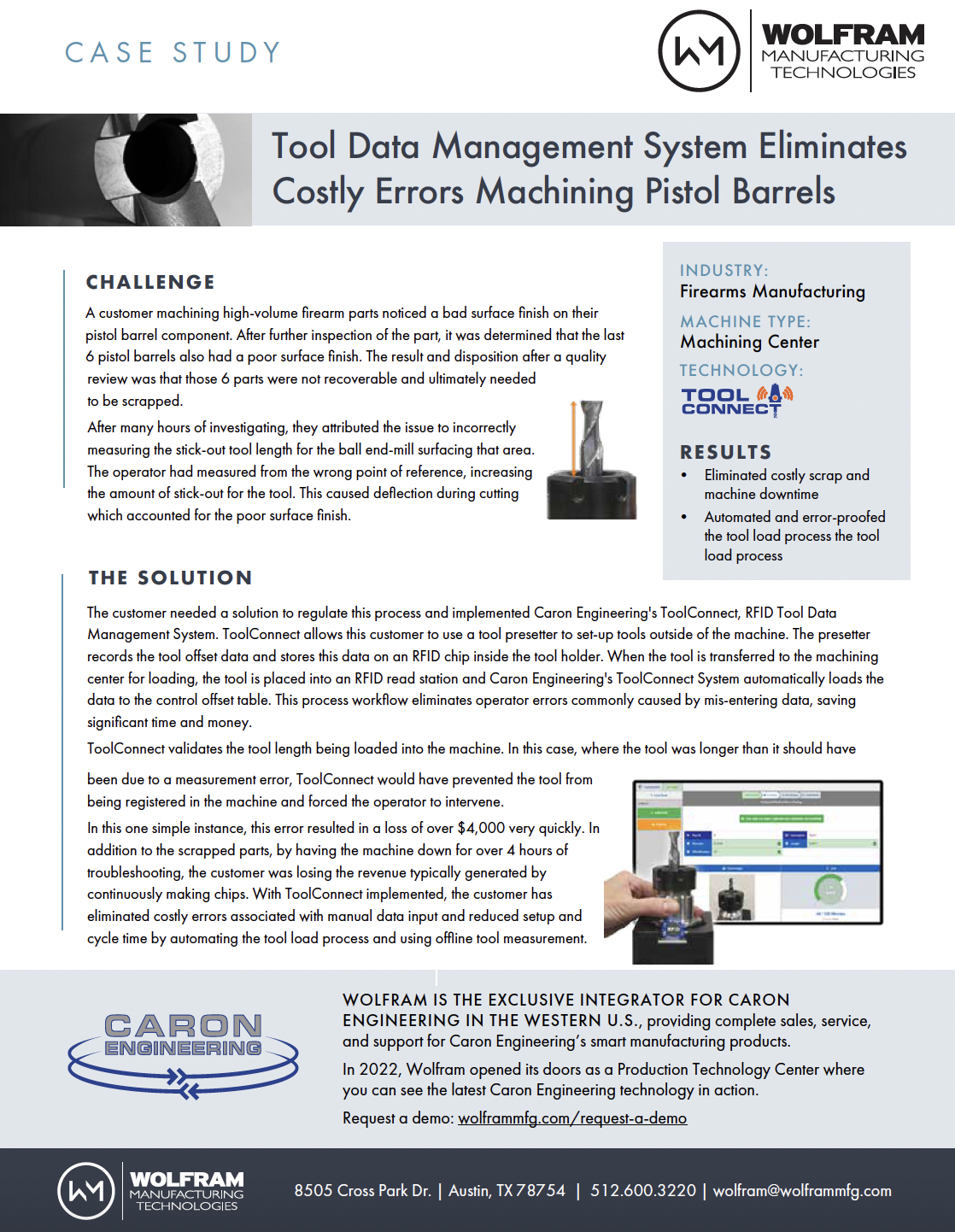

ToolConnect Case Study

Learn more about how a single operator error cost a firearm manufacturer $4,000 due to improper tool setup and how these errors are prevented with ToolConnect from Caron Engineering.

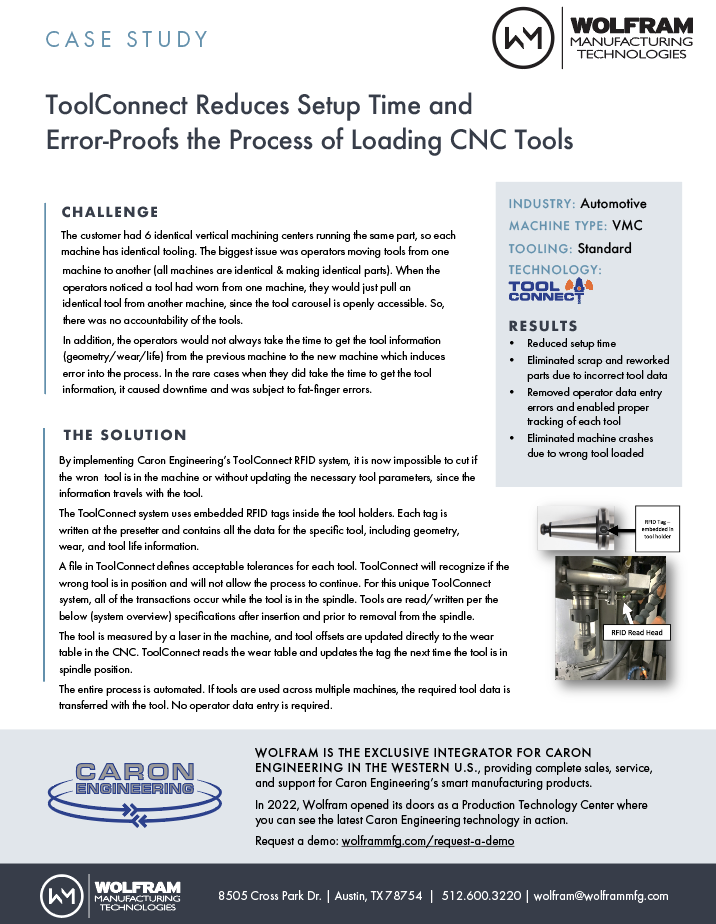

ToolConnect Reduces Setup Time & Error-Proofs the Loading of CNC Tools

Learn how an automotive customer reduces setup time, reduces scrap, eliminates operator data entry errors, and stops machine crashes using ToolConnect from Caron Engineering on their Vertical Machining Center.

AutoComp Case Study

Learn more about how an aerospace manufacturer eliminated scrap of a critical component by leveraging AutoComp to adjust work offsets automatically.

AutoComp Increases Productivity by 200%

Download the AutoComp Case Study to learn how to a contract manufacturer increased productivity by 200% with help from AutoComp on their Tsugami swiss CNC machines.

AutoComp Case Study

Download the AutoComp Case Study to learn how an aerospace manufacturer implements AutoComp to automate 100% inspection of components without an operator.

DTect-It Case Study

Download the DTect-It Case Study to learn how a customer significantly reduced scrapped components with DTect-IT from Caron Engineering on their Tsugami Swill Lathe.

DTect-It Enables Robotic Automation

Download the DTect-It Case Study to learn how a medical manufacturer used DTect-It with a Keyence sensor to overcome the accuracy issues of a robot loading a rod into a vertical machining center. Data from DTect-It enabled the VMC to offset the work coordinates to increase the accuracy of the component.

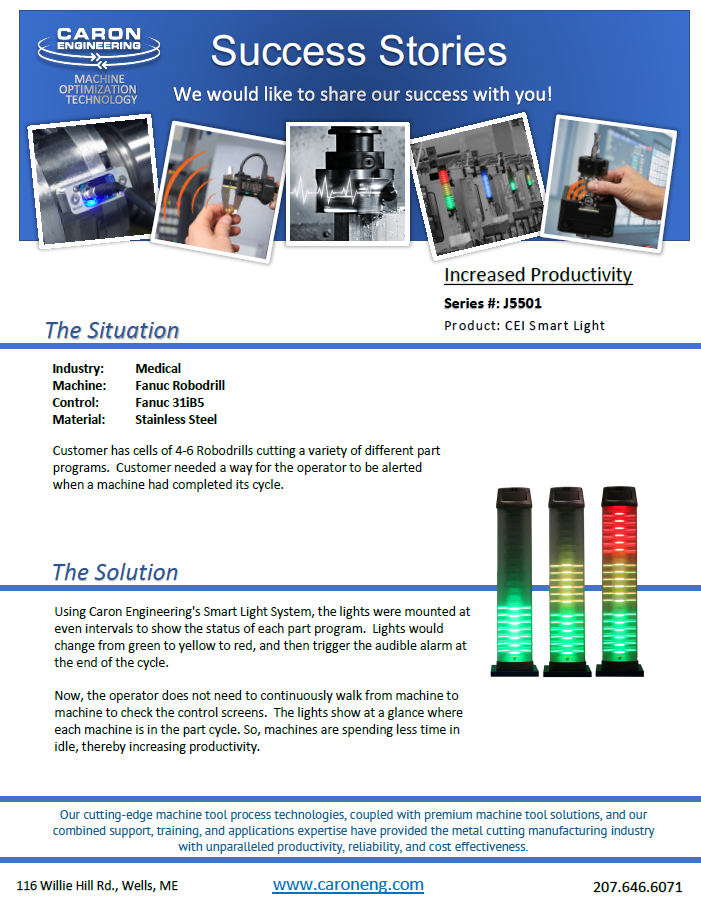

SmartLight Case Study

Learn more about how a medical manufacturer leveraged the SmartLight from Caron Engineering on their Fanuc RoboDrills to minimize operators walking from machine to machine to understand the current status.