Save $1,400 tracking variables with OnTakt

Tracking historical data part by part can drive continuous improvement at your shop

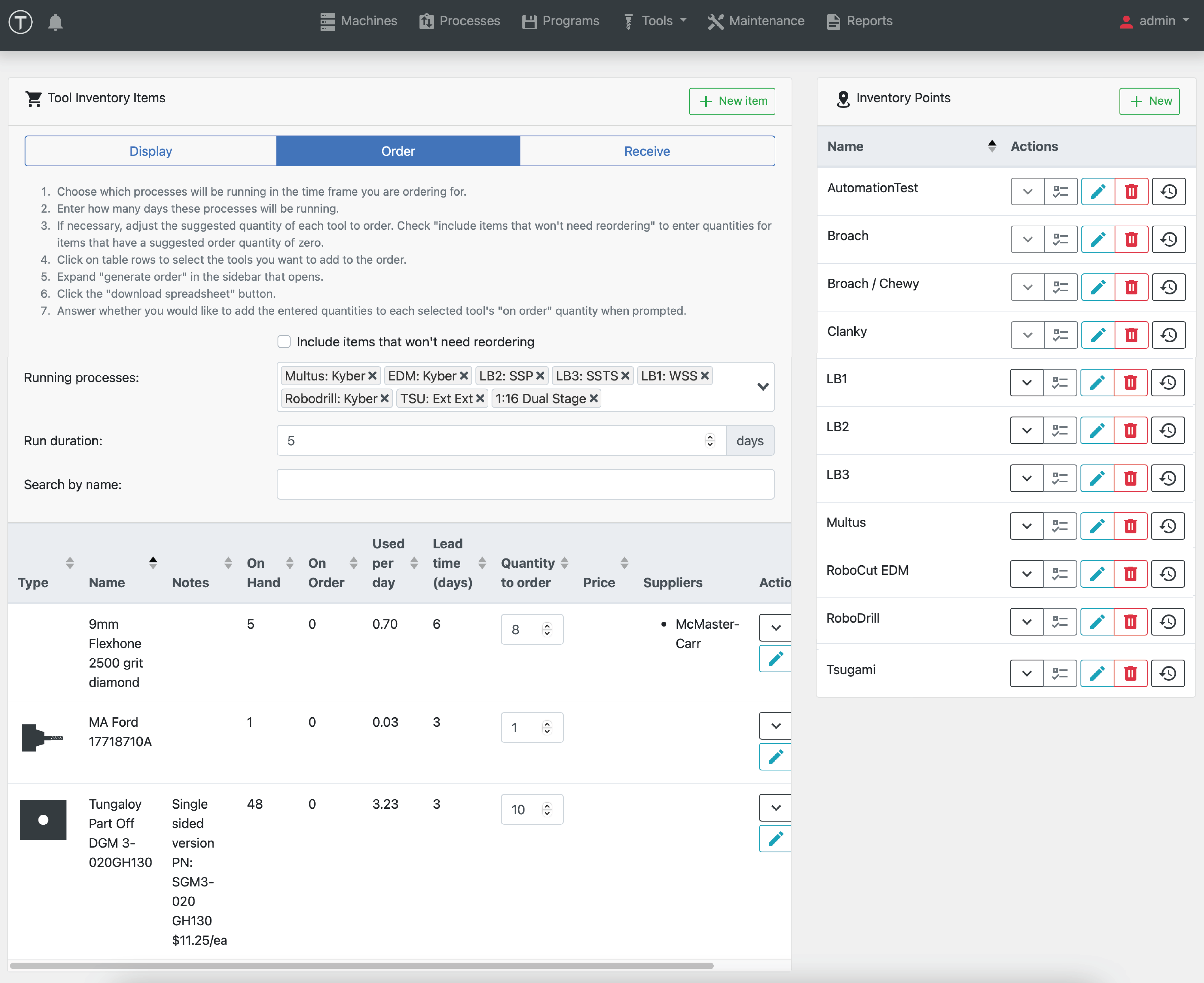

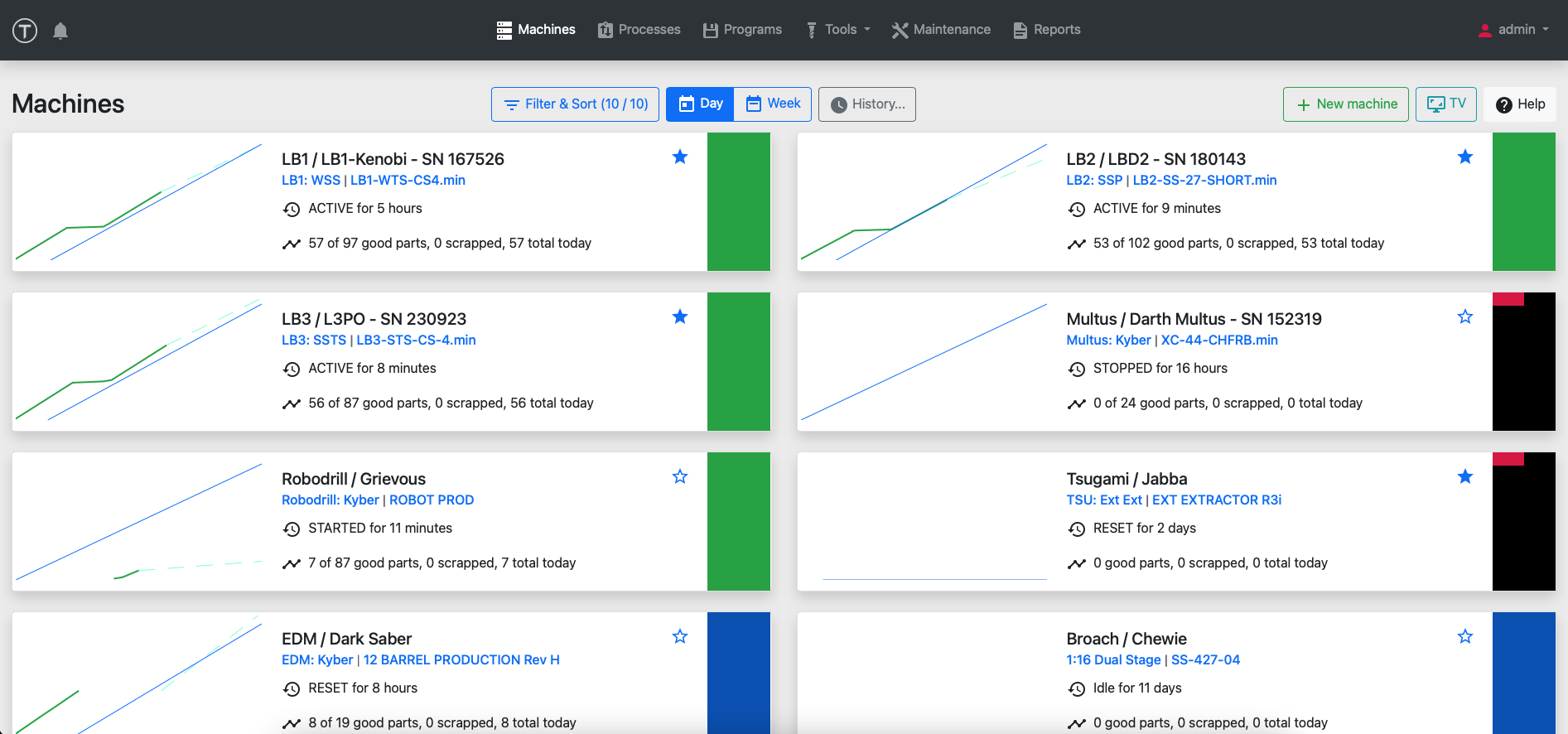

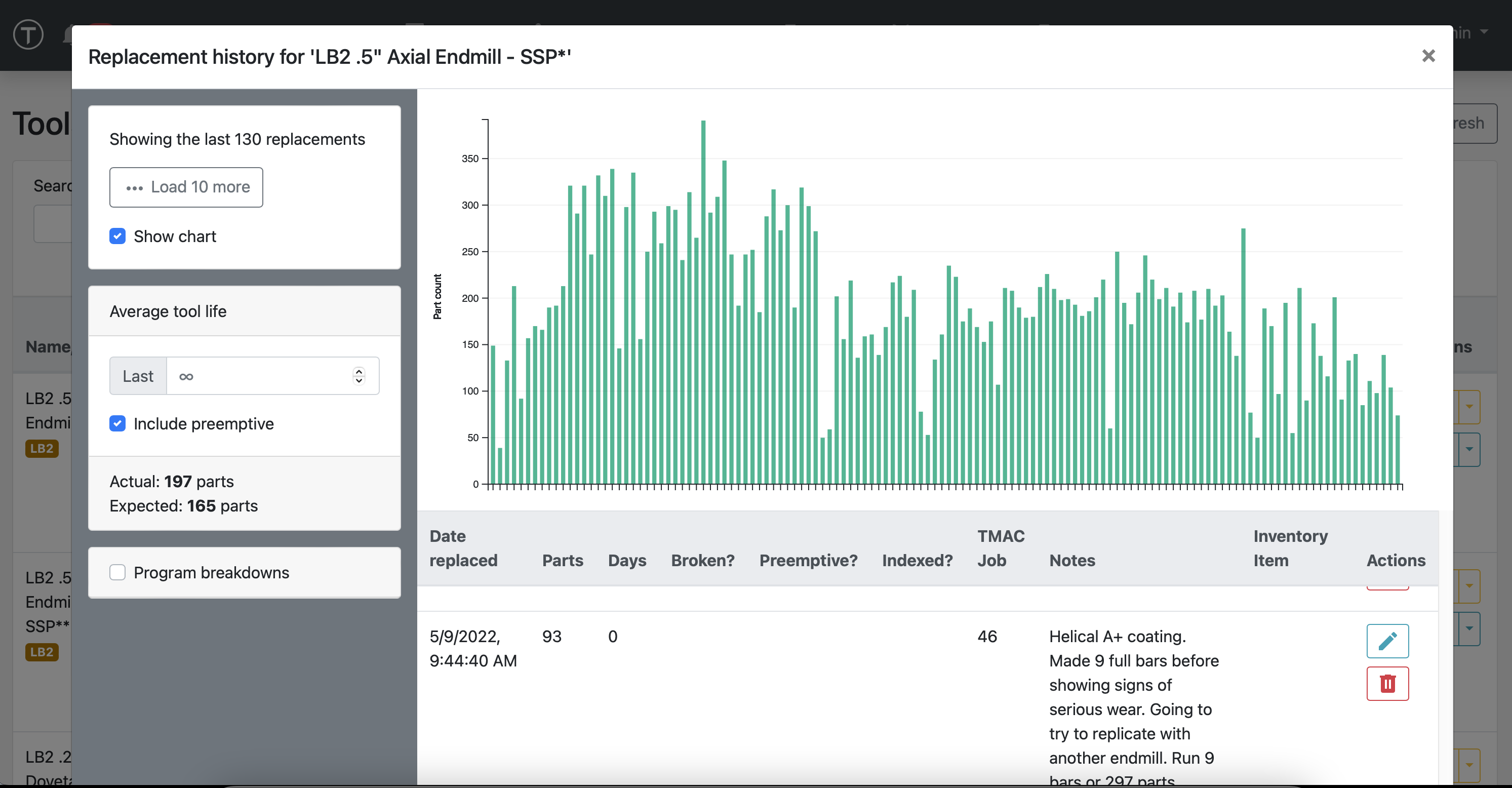

OnTakt has the ability to track macro or common variables in your CNC machines. In this video we show you how you can look at historical data captured in OnTakt to drive continuous improvement at your shop. In this quick example we saved $1,400 in scrapped parts by:

- Identifying an issue through data captured with an in-machine probe

- Finding a potential solution to the problem

- Proving that we solved the problem through data captured after the fix was put in place

Watch how we set up and track variables in OnTakt as well as how we analyzed the data to identify the issue: LOOM VIDEO

COST SAVINGS WITH ONTAKT

1

Week until the fix paid for itself

2.5

Months until this fix paid for one year of OnTakt

1

Year of Maintenance Costs for OnTakt, Paid for Every Single Month