Reduce Tooling Costs with OnTakt

Identify a new tool or lot of tools that cause production problems

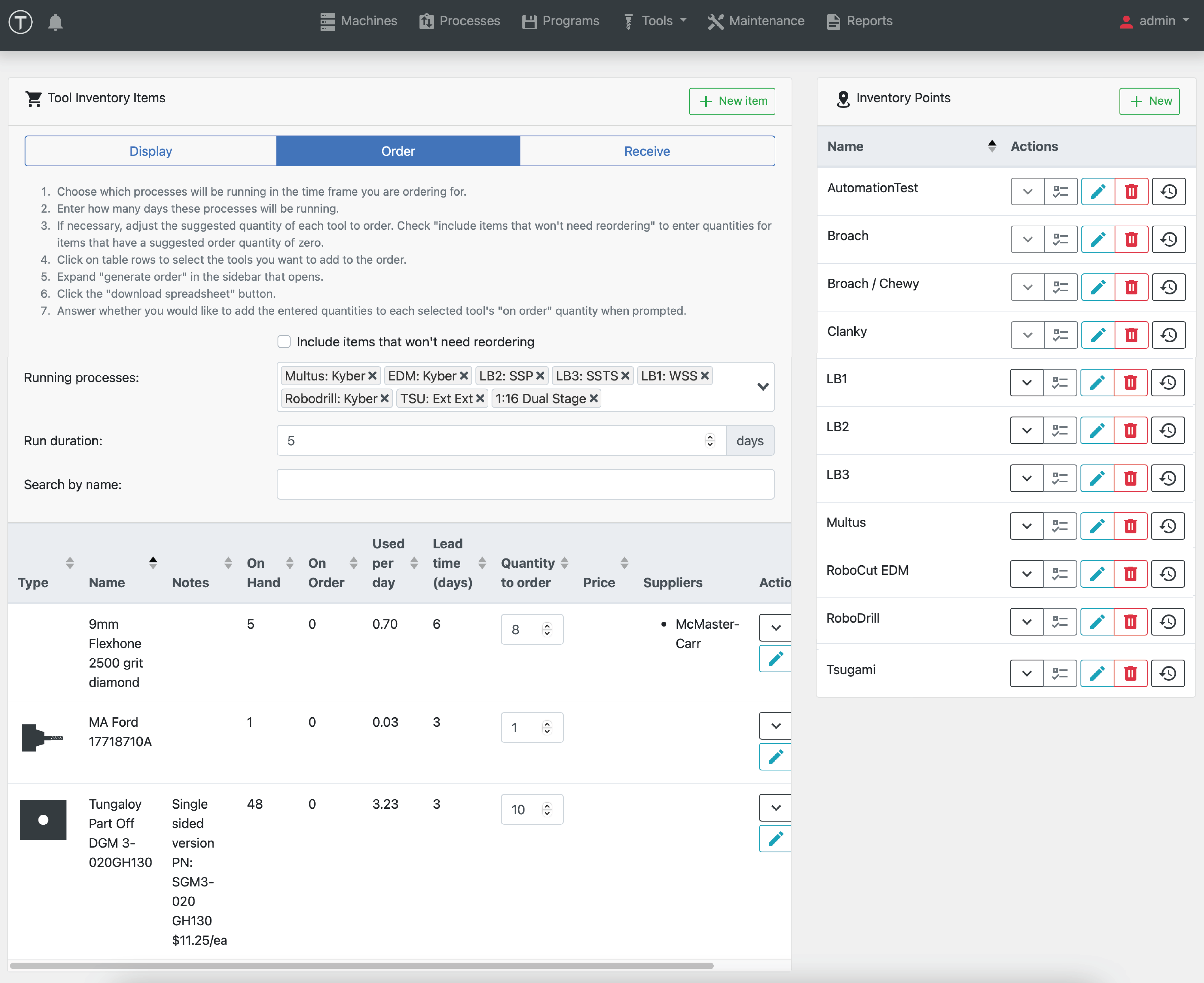

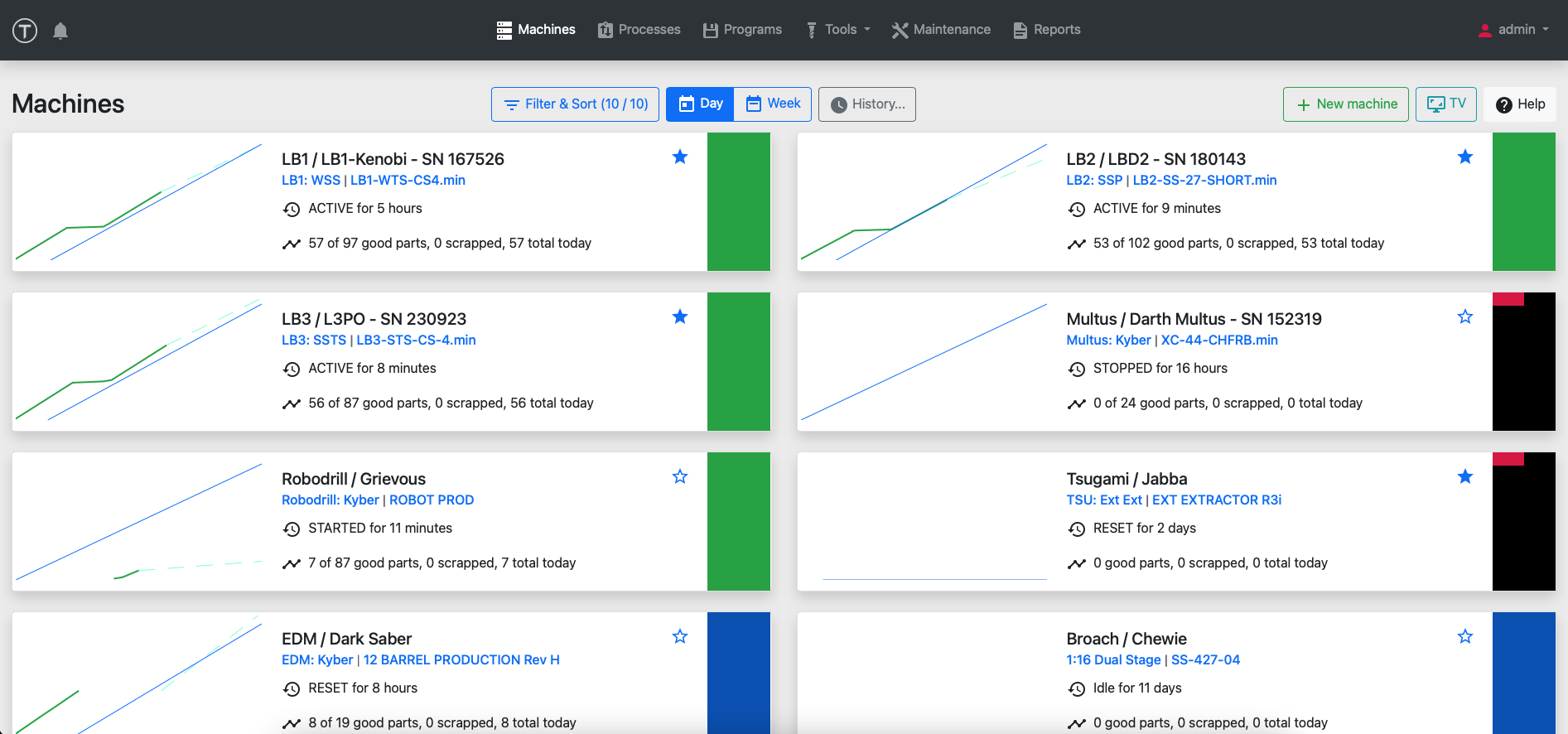

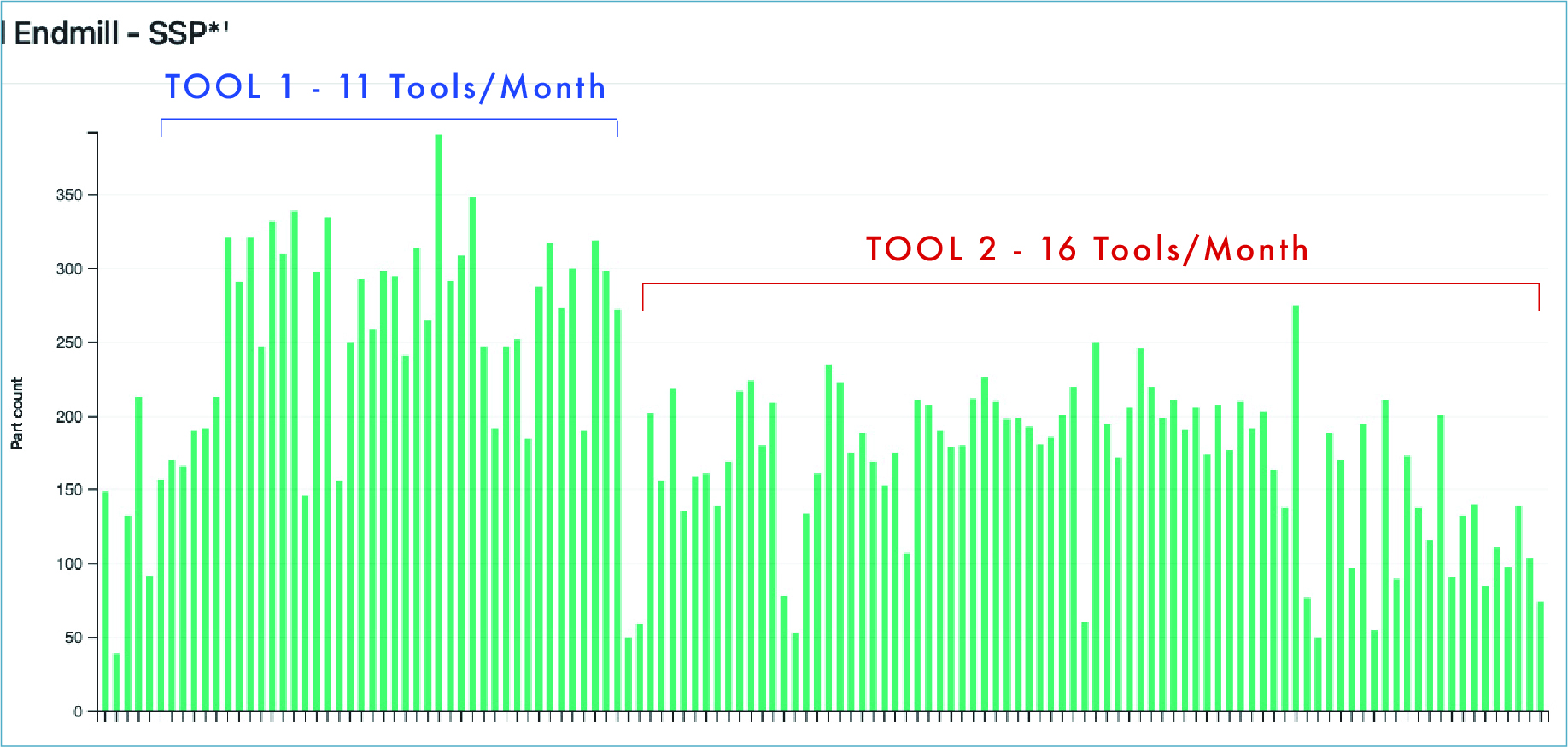

Every month, OnTakt will easily pay for itself by identifying the tools causing production problems. By monitoring the OnTakt tooling module, an operator can quickly assess when consumable and durable tools are either underperforming or providing better than expected tool life. By tracking tool life with OnTakt, operators and supervisors will have a clear picture of true tool life, leading to smarter decisions about when to change tools and/or drives and when to switch to a different tool to optimize tool life. With an accurate picture of tool life, a shop can lean harder on real data to support decisions rather than on the traditional method of relying on highly skilled operators to listen and feel for what is happening on a machine.

COST SAVINGS WITH ONTAKT

$385

SAVINGS PER MONTH

Savings each month on just one 1/2” endmill with clear visibility of tool life.

1.8

MONTHS

ROI YEAR 1

0.6

MONTHS

ROI YEAR 2+

TOOLS THAT PERFORM CONSISTENTLY improve your run quality with less troubleshooting and reduced machine downtime

GAIN CLEAR INSIGHTS into tool life to significantly reduce tooling costs

IDENTIFY TRENDS with durable and consumable tooling to make smarter inventory and predictive maintenance plans

THE ONTAKT TOOLING MODULE identifies tooling that is consistent for your process while also reducing problems that lead to quality issues, surface finish changes, extra deburring, and more

Conservative Tool Targets

OnTakt integrated with TMAC leads to a savings of $2,000 per machine every month on consumable tooling alone

OnTakt and TMAC from Caron Engineering are designed to be tightly integrated. Leveraging data from both systems simultaneously leads to significant savings on tooling. In our own production shop we are able to safely push tools further into their tool life by using TMAC to stop machines when tools wear or break prematurely. By pairing TMAC with tool life data tracked and recorded in OnTakt, we can easily identify trends to decide when to look into poorly performing tools or identify process changes that need attention. This type of data is often lost on a shop floor. But presenting it clearly, to all levels of an organization, can lead to significant cost savings with rapid ROIs. OnTakt and TMAC will rapidly pay for themselves after finding even one tool that could benefit from more aggressive tool life.

COST SAVINGS

$2,000

SAVINGS PER MONTH

Extra tool life saves $2,000 in tooling per month per machine by driving 5 endmills and 5 insert tools longer with protection by TMAC.

9

9

MONTHS

ROI YEAR 1 OF ONTAKT INTEGRATED OF TMAC

3

MONTHS

ROI YEAR 2+ OF ONTAKT INTEGRATED OF TMAC