Reduce Operator/

Employee Costs

Use OnTakt to enable “drop-in” shifts where operators can predict tool changes and prevent machine stoppages on unattended shifts.

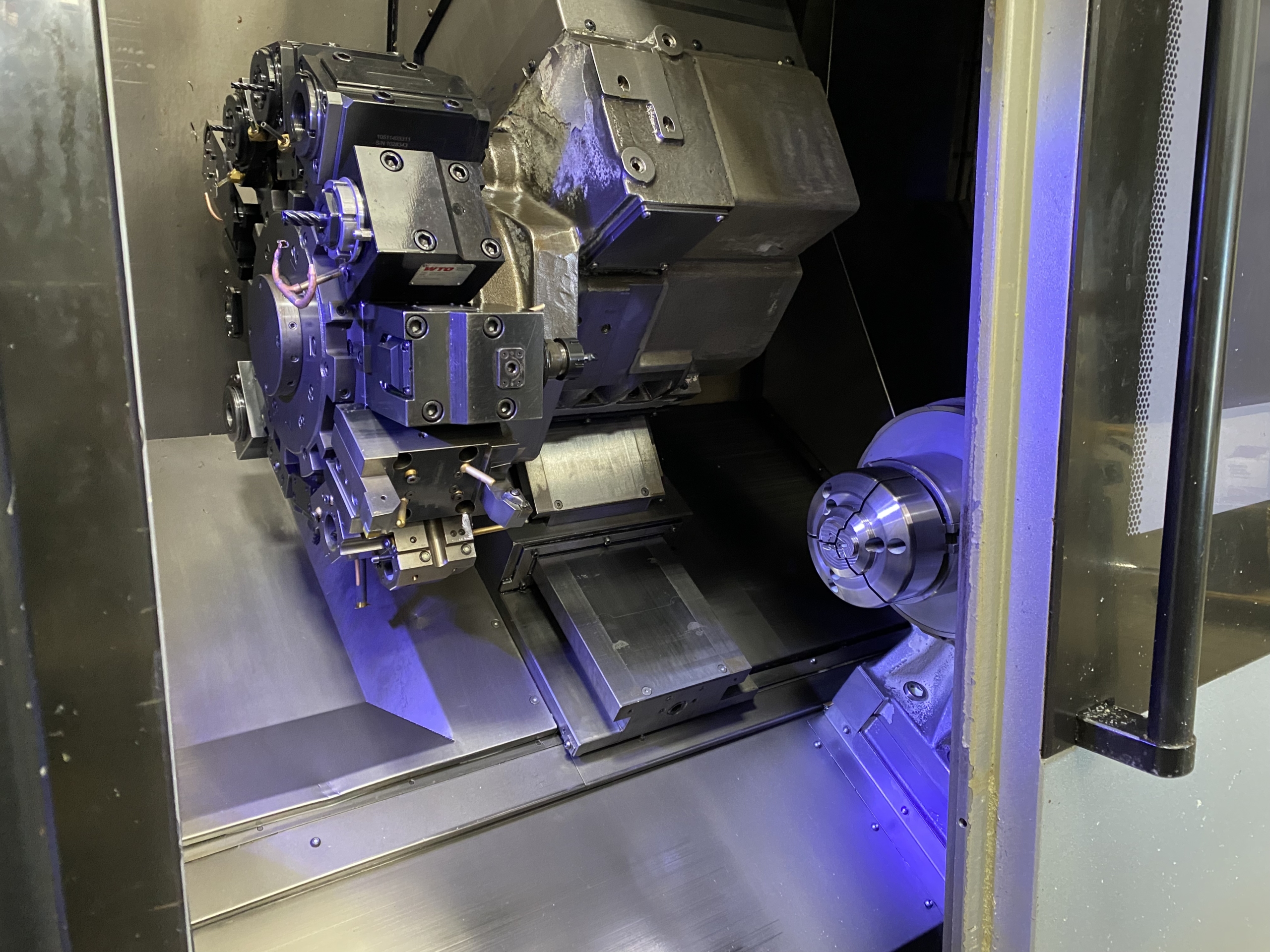

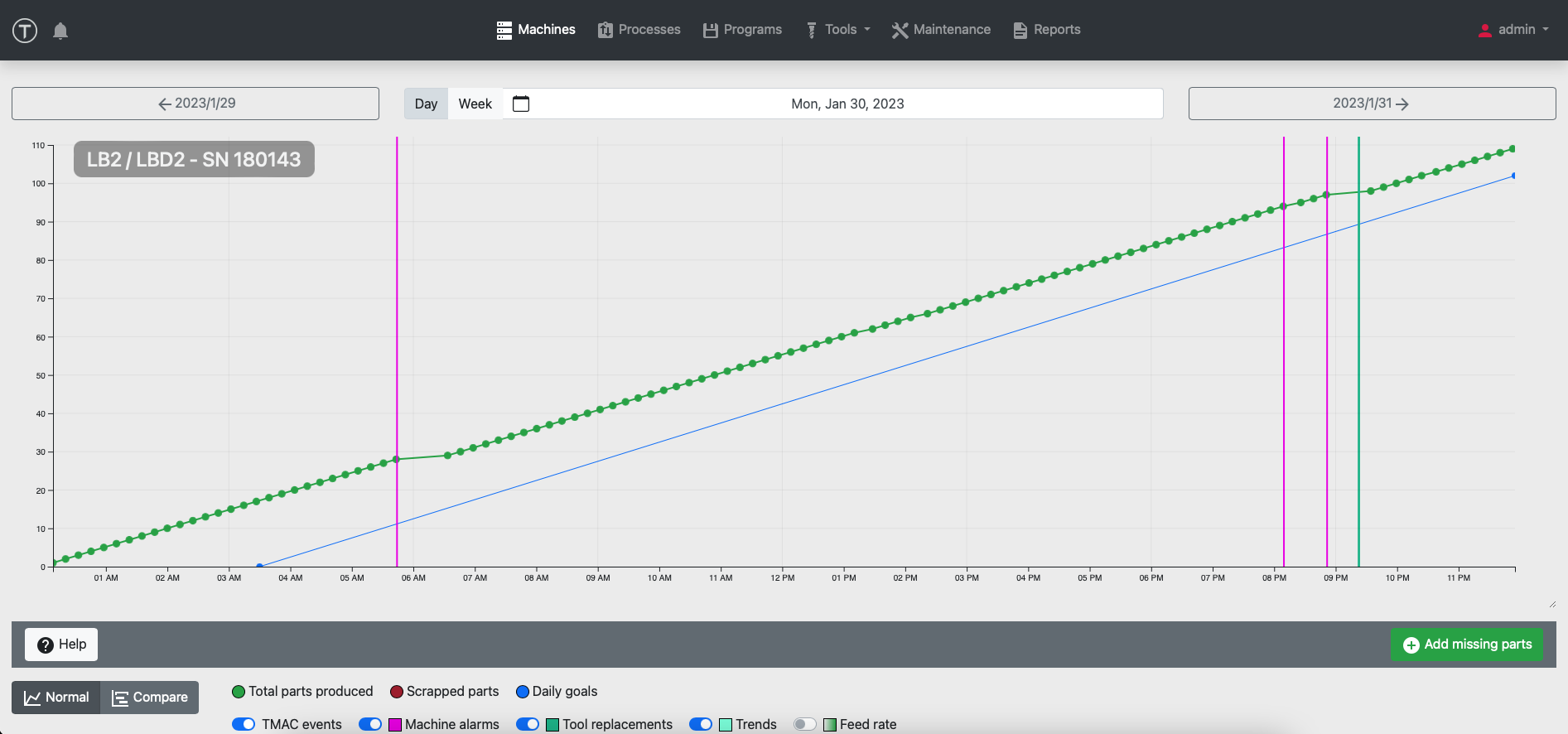

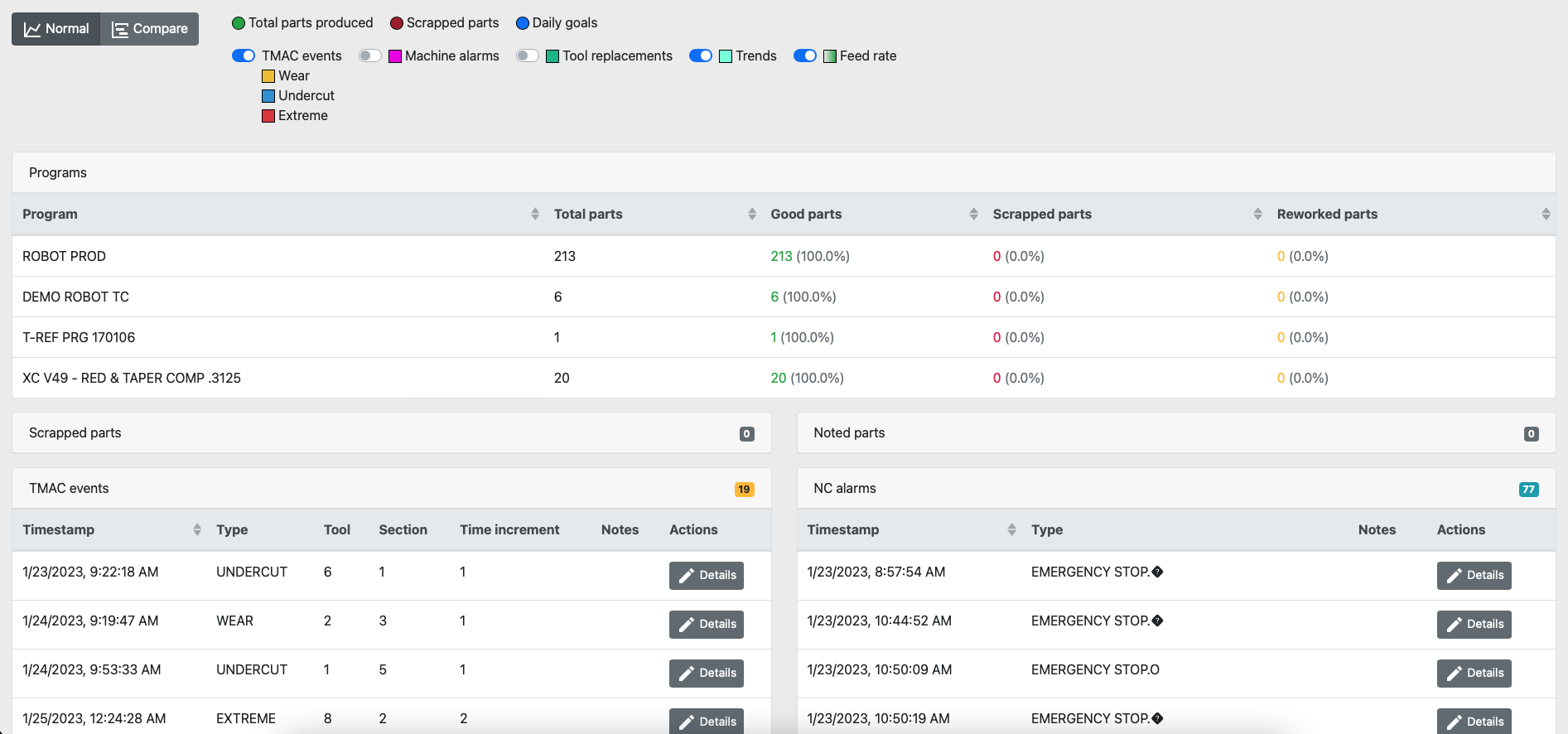

A shop can adopt “drop-in” shifts once it’s possible to predict an upcoming tool change. Leveraging TMAC from Caron Engineering gives our shop the confidence to run our machines unattended by significantly reducing the risk of damage from broken tools to parts or machines. While TMAC is an excellent addition to begin the automation process, it doesn’t predict when a planned tool change will occur. With OnTakt, when an operator arrives for a drop-in shift they can quickly assess if a machine is expecting to have additional tool changes later in their shift. If multiple tool changes are expected, the tool can be changed preemptively to help avoid a machine stoppage. Increasing your unattended run quality can lead to significant profitability gains by running more parts unattended with little operator input.

COST SAVINGS WITH ONTAKT

4

HOURS OF STOPPAGE

6

HOURS OF OPERATOR TIME SAVED

4.2

MONTHS

ROI YEAR 1

1.4

MONTHS

ROI YEAR 2+

LIGHTS OUT MACHINING enabled by TMAC from Caron Engineering

ELIMINATE MACHINE STOPPAGES from predictable tool changes to lead to significant productivity gains per month

ENABLE OPERATORS TO VISUALIZE UPCOMING TOOL CHANGES to improve run quality, resulting in longer unattended runs and more frequent ‘drop-in’ shifts

Reduce the amount of time it takes a supervisor to understand production.

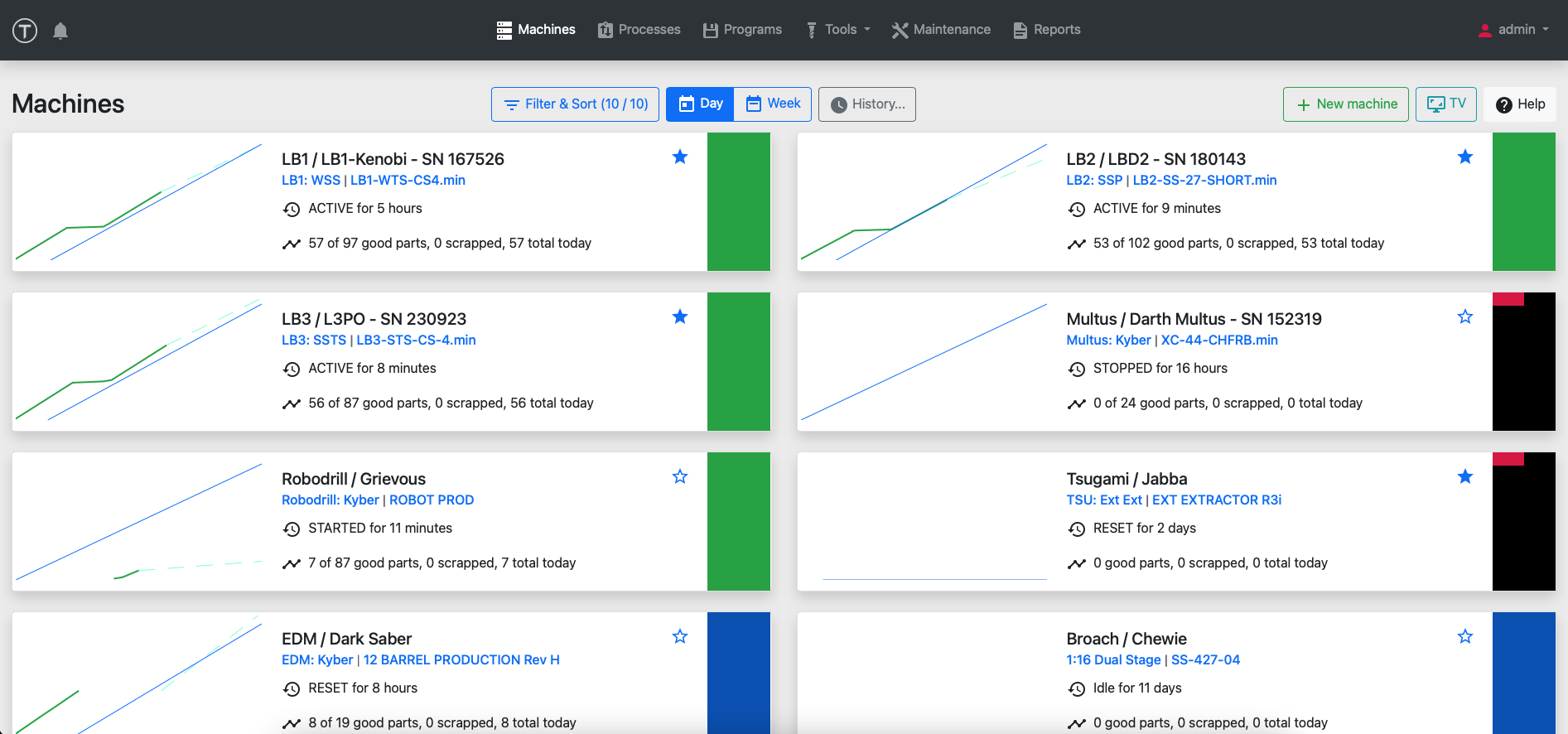

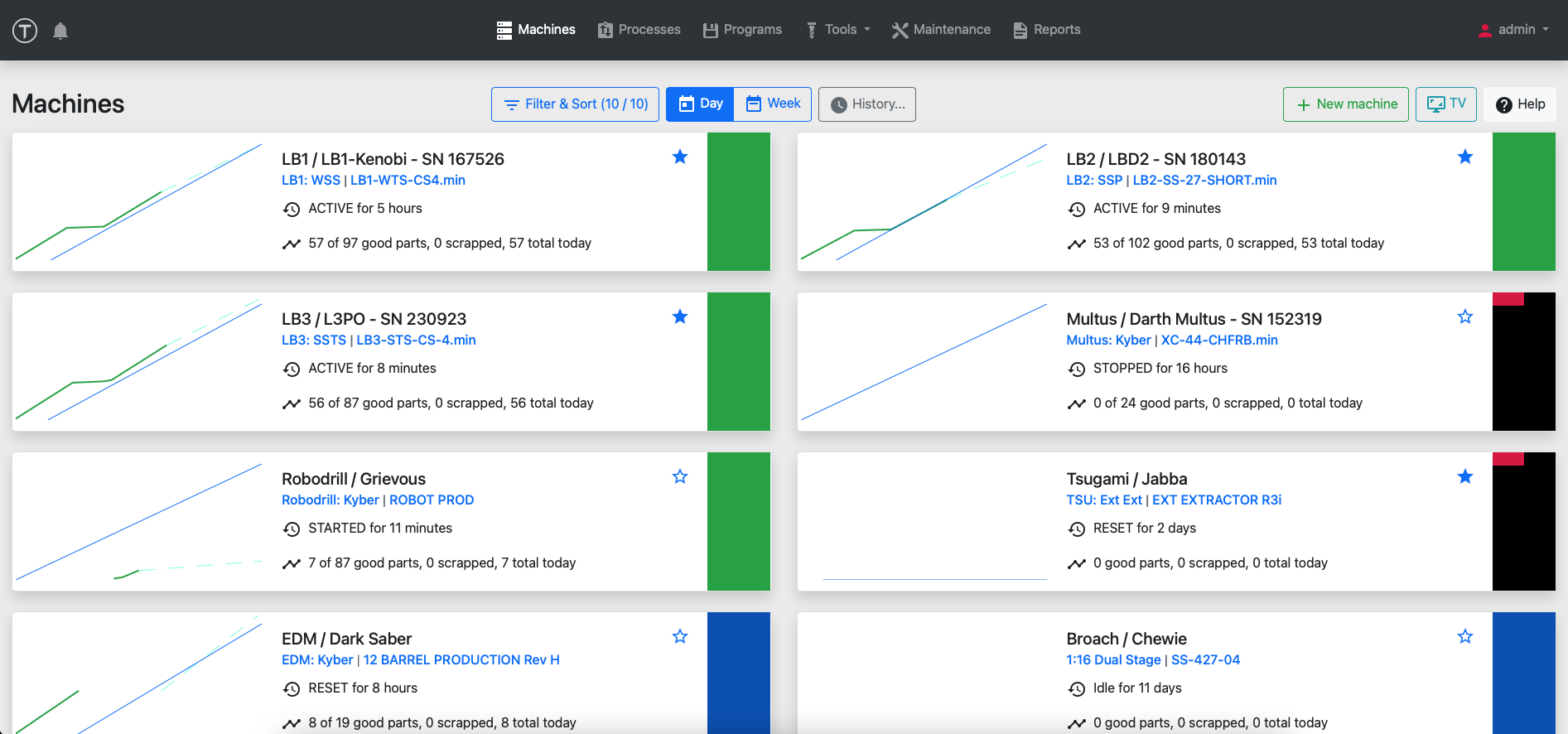

OnTakt Machine Cards

Quickly visualize machine status and production targets to triage areas on the shop floor that need additional attention.

OnTakt Machine Detail

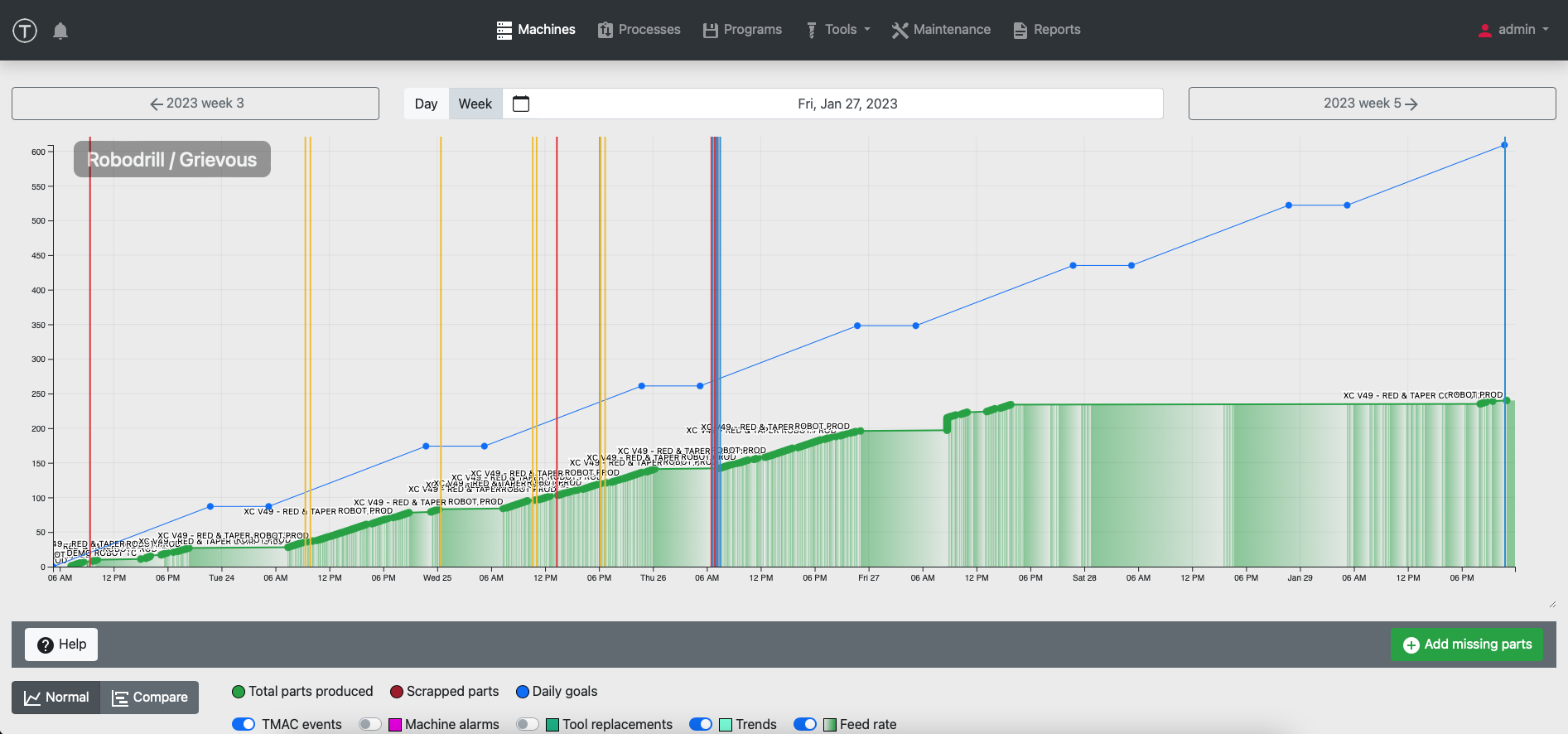

Visualize an individual machine’s production status and identify unexpected machine stoppages or slower than expected cycle times

Reducing the amount time that a supervisor must “walk the floor” allows the focus to shift from data collection to problem solving.

OnTakt was designed with two major goals in mind:

- To be able to quickly understand the state of production.

- To quickly answer the first 5-10 questions about a problem before heading to the shop floor.

To understand the shop floor, a user does not need to continuously report the exact state of every machine. The rapid on/off of flashing lights tends to desensitize the user. We call this the disco ball effect. With OnTakt, if a machine stops, the colors that identify the machine state change slowly over time. With our built-in Slack/MS Teams notifications it is likely that one of our operators is already attending to a machine stoppage. Within a few minutes that machine is likely to be up and running. If a machine stays stopped for an extended period of time, the colors representing that machine will slowly drift to notify the user that more attention is needed at that machine.

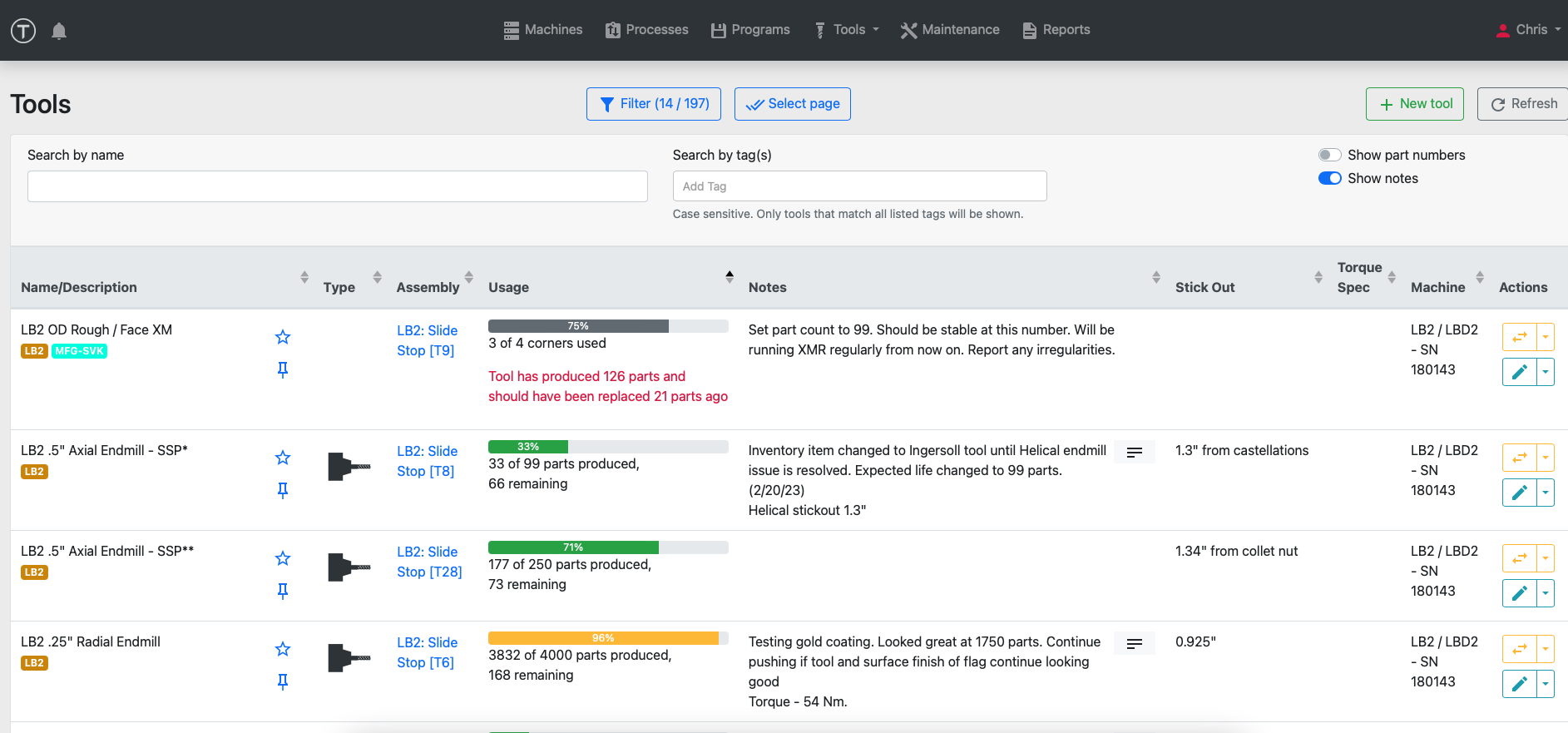

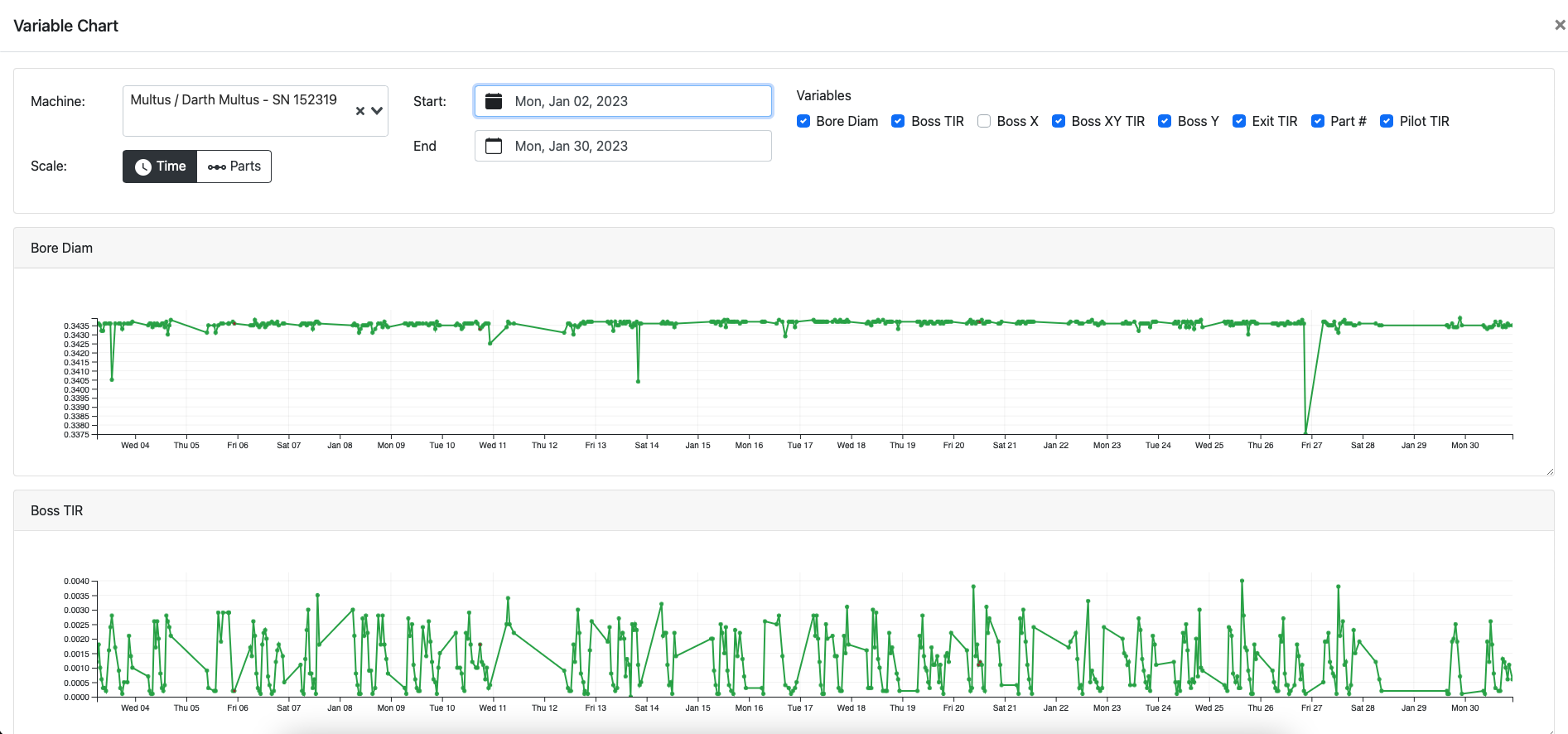

If an issue arises that a supervisor needs to attend to, OnTakt is designed to immediately triage the situation to understand the problem. OnTakt provides a host of automatic and user generated data that includes information like machine alarms, the current life of all consumable and durable tools in the machine, in-machine inspection and variable data, currently loaded programs, part counts (good and scrapped), and machine feed rates. This immediate access to data speeds up the understanding of a downtime situation to improve run quality and ensure that a machine has as much spindle uptime as possible.

OnTakt Tool Status

Track and Chart Macro Variable Data

Machine Data Summary

Feed Rate Chart

COST SAVINGS WITH ONTAKT

15

MINUTES PER WEEK

Justify the cost of OnTakt every month on every machine by saving 15 minutes a week finding reliable information and gathering data to solve production problems.

3

MONTHS

ROI YEAR 1

1

MONTH

ROI YEAR 2+

QUICKLY TRIAGE PROBLEMS to improve run quality by getting machines back online faster

GAIN REAL-TIME ACTIONABLE DATA with quick access to production data

FILTER INFORMATION to quickly identify issues and make decisions in real-time

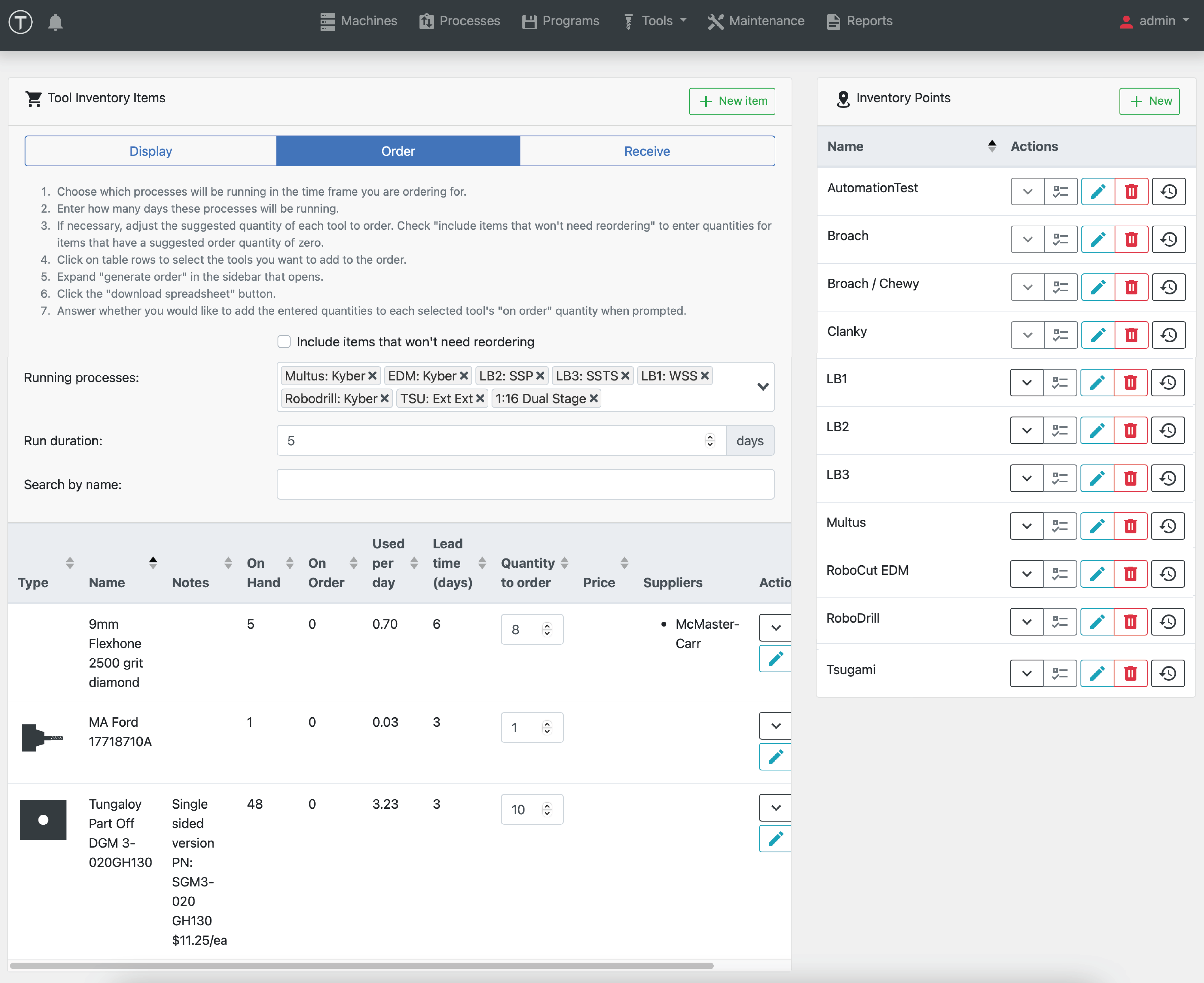

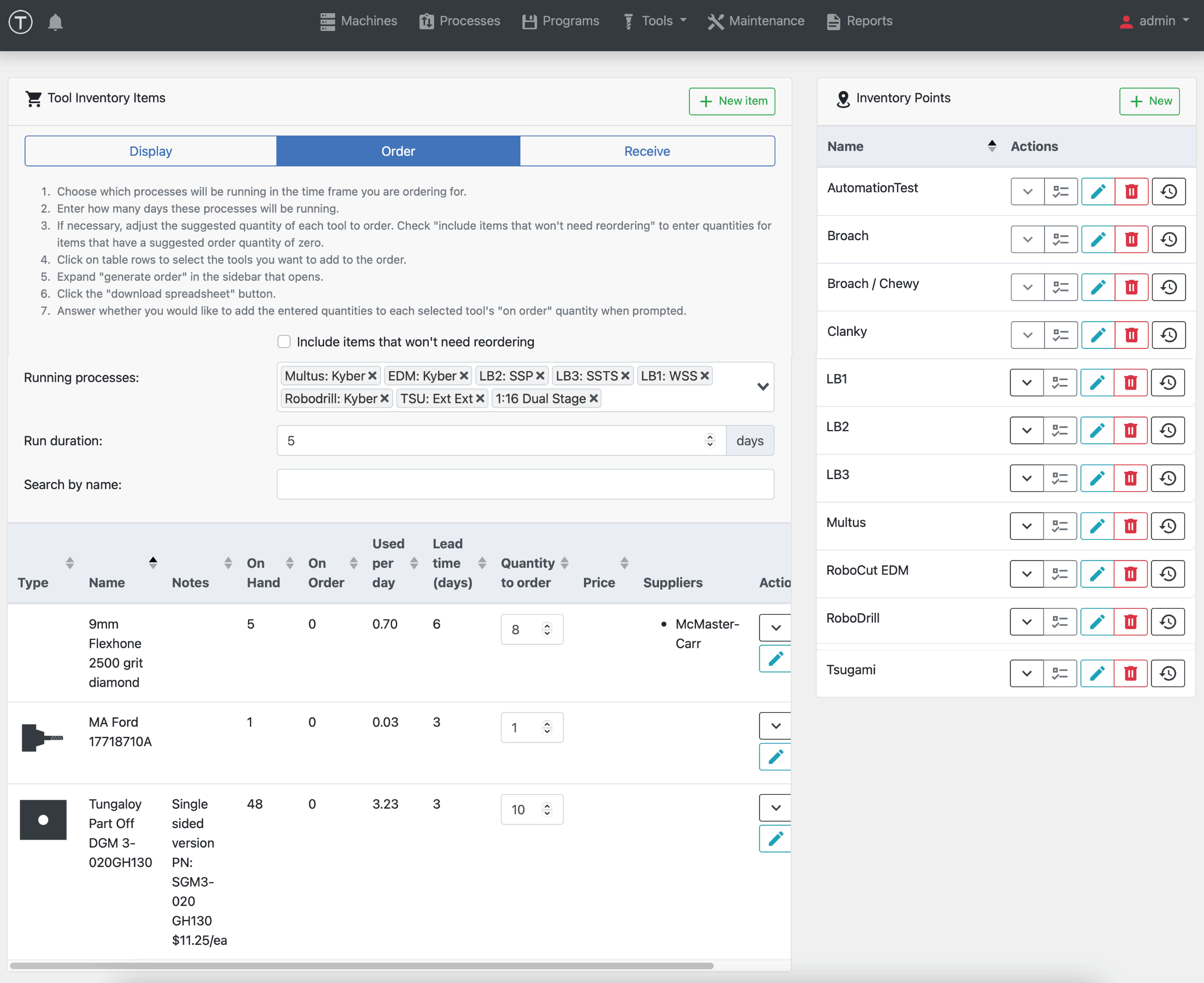

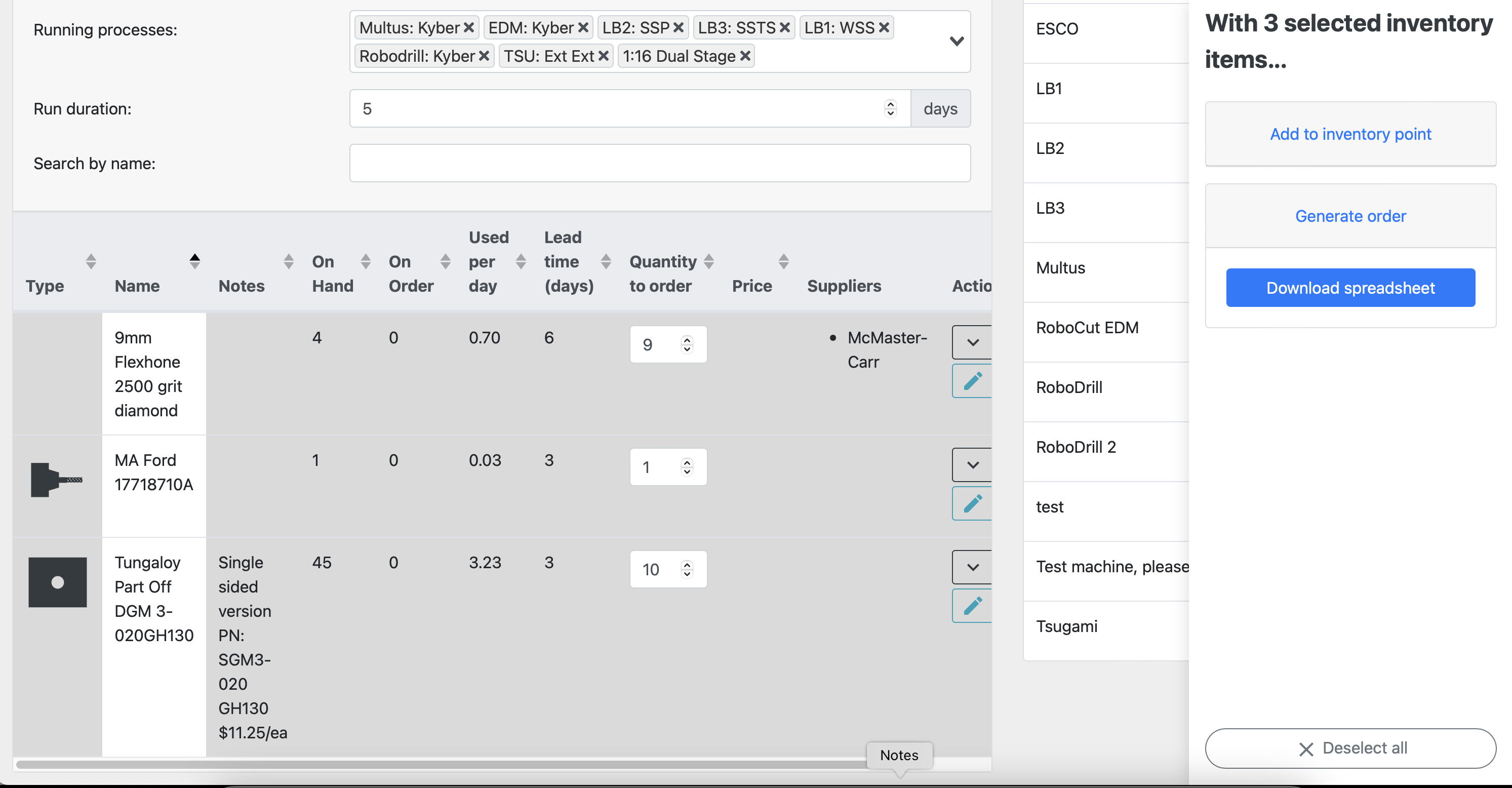

Reduce the amount of time it takes to order tooling

OnTakt has a built in inventory module that allows the user to track tooling. It tracks multiple stock locations throughout the shop and provides notifications to reorder tools to prevent tooling stockouts. The inventory module makes it easy for your operations/purchasing team to quickly identify what needs to be ordered and exports all of the necessary data (vendors, part numbers, descriptions, quantities, and more) that can be forwarded to vendors for purchasing. The OnTakt inventory module eliminates the need to invest in an expensive inventory management system while reducing the time commitment necessary for your team to order, track, and receive tooling.

OnTakt Tool Ordering Visualization

OnTakt Tool Ordering

COST SAVINGS

12

MONTHS

ROI YEAR 1

4

MONTHS

ROI YEAR 2+

REDUCE THE TIME needed to understand tooling inventory and place tooling orders with the OnTakt tooling module

ELIMINATE CONFUSION on the shop floor due to misplaced tooling with shop-wide inventory tracking

ENABLE ANYONE in the shop to receive and place tooling in proper inventory locations