Prevent Unexpected Machine Stoppage with OnTakt

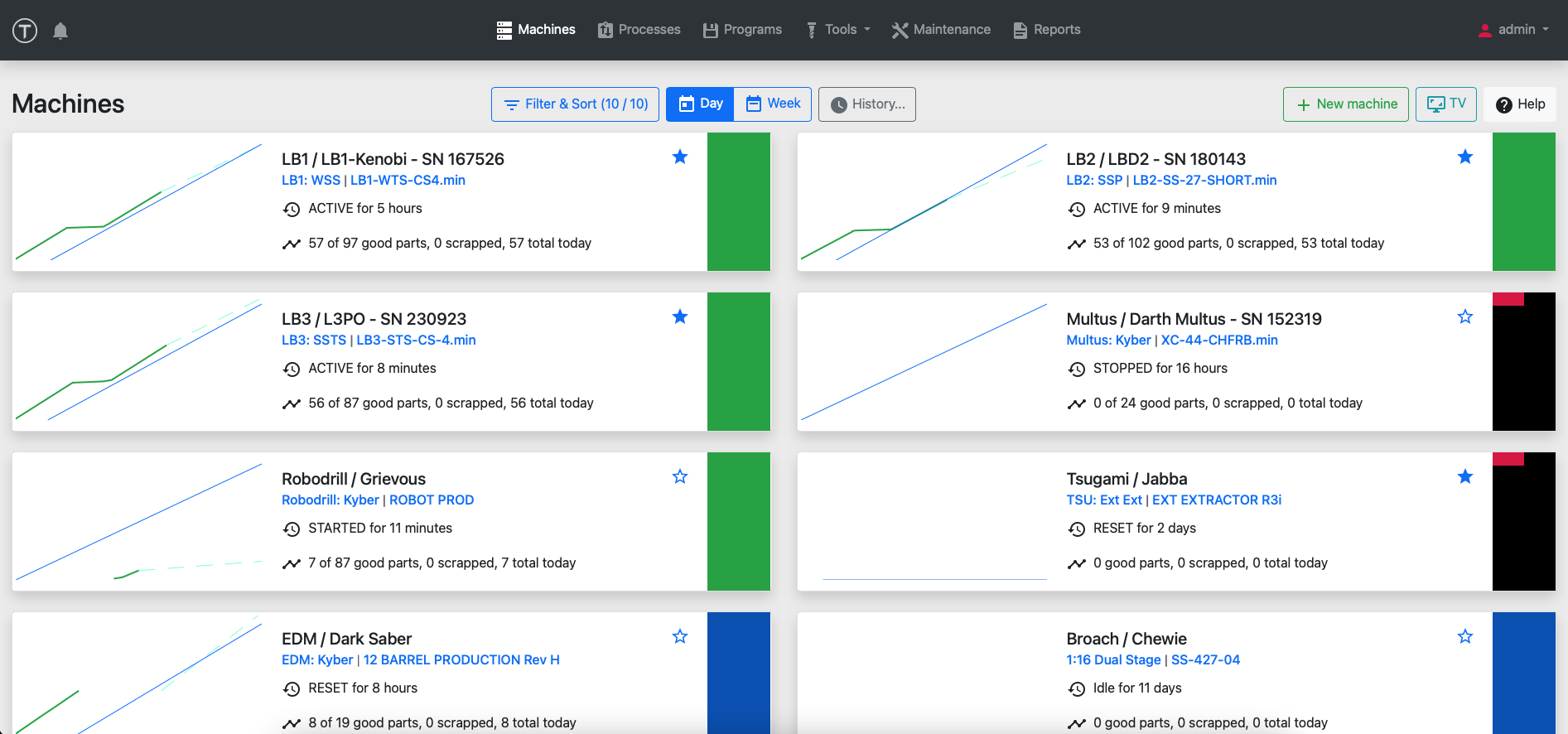

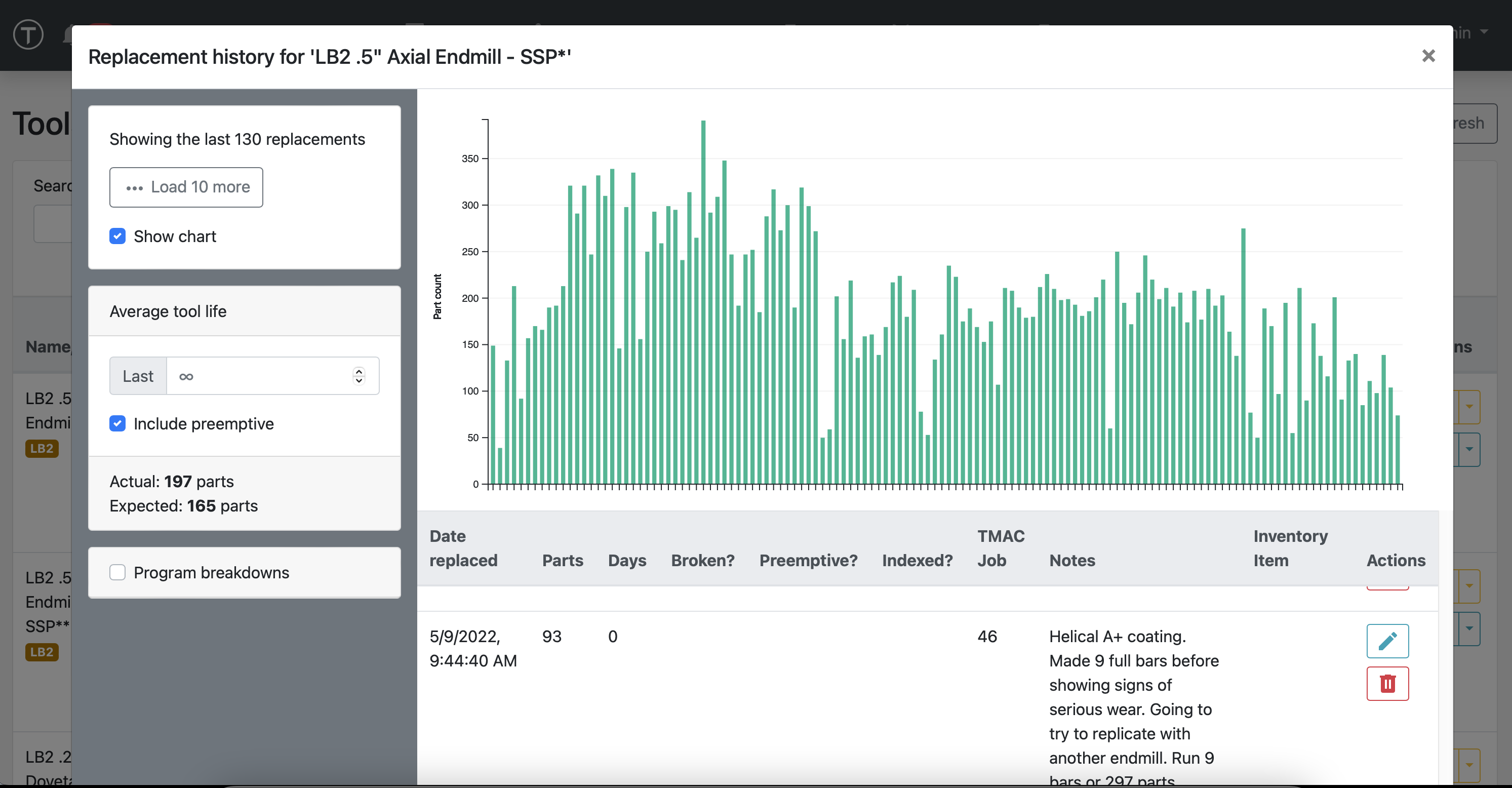

When a machine stops for a routine tool change most of the downtime is spent waiting for an operator to begin the tool change. OnTakt makes it possible to group tool changes for tools that will expire in the near future, reducing downtime. On a second shift with limited operators, a tool change can lead to longer machine downtime or completely stop an overnight unattended run.

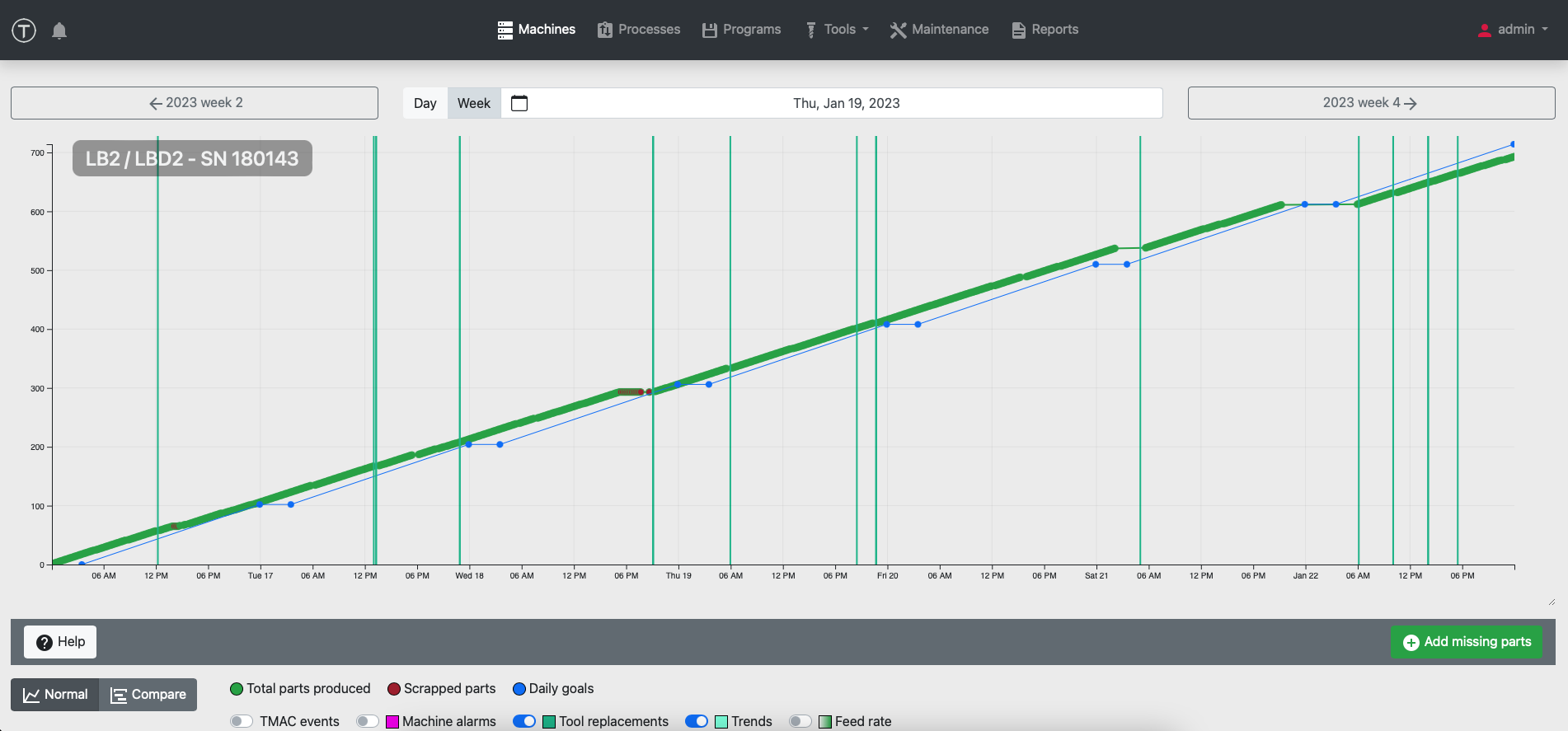

Group tool changes with OnTakt to minimize downtime.

Cost Savings with OnTakt

20

MINUTES PER PREEMPTIVE CHANGE

3

STOPS PER WEEK

4

HOURS PER MONTH

$400

SAVINGS PER MONTH

9

MONTHS

ROI YEAR 1

3

MONTHS

ROI YEAR 2+

PREEMPTIVELY CHANGE TOOLS that will expire soon

CHANGE TOOLS PRIOR TO AN UNATTENDED RUN to prevent a machine from stopping overnight

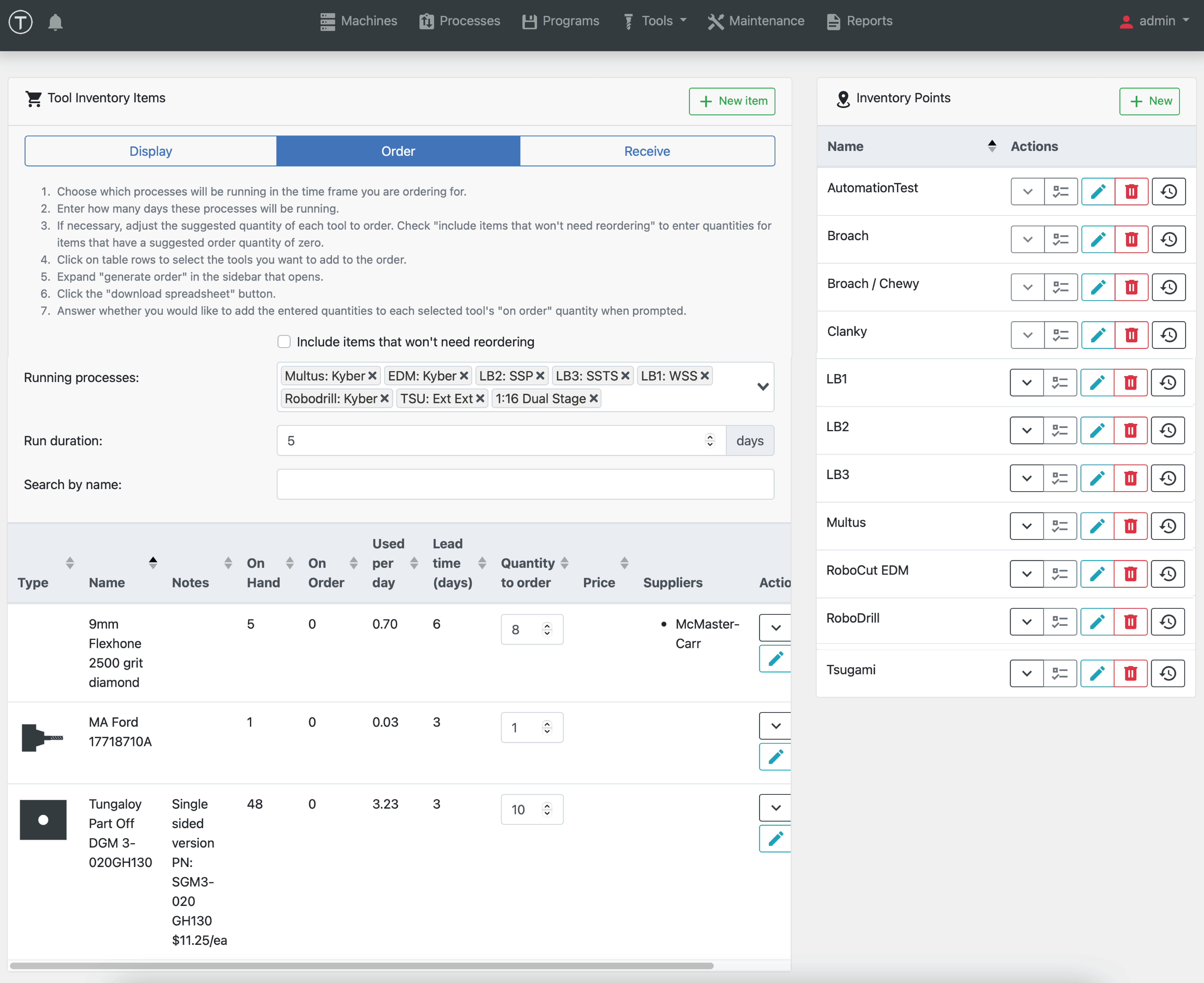

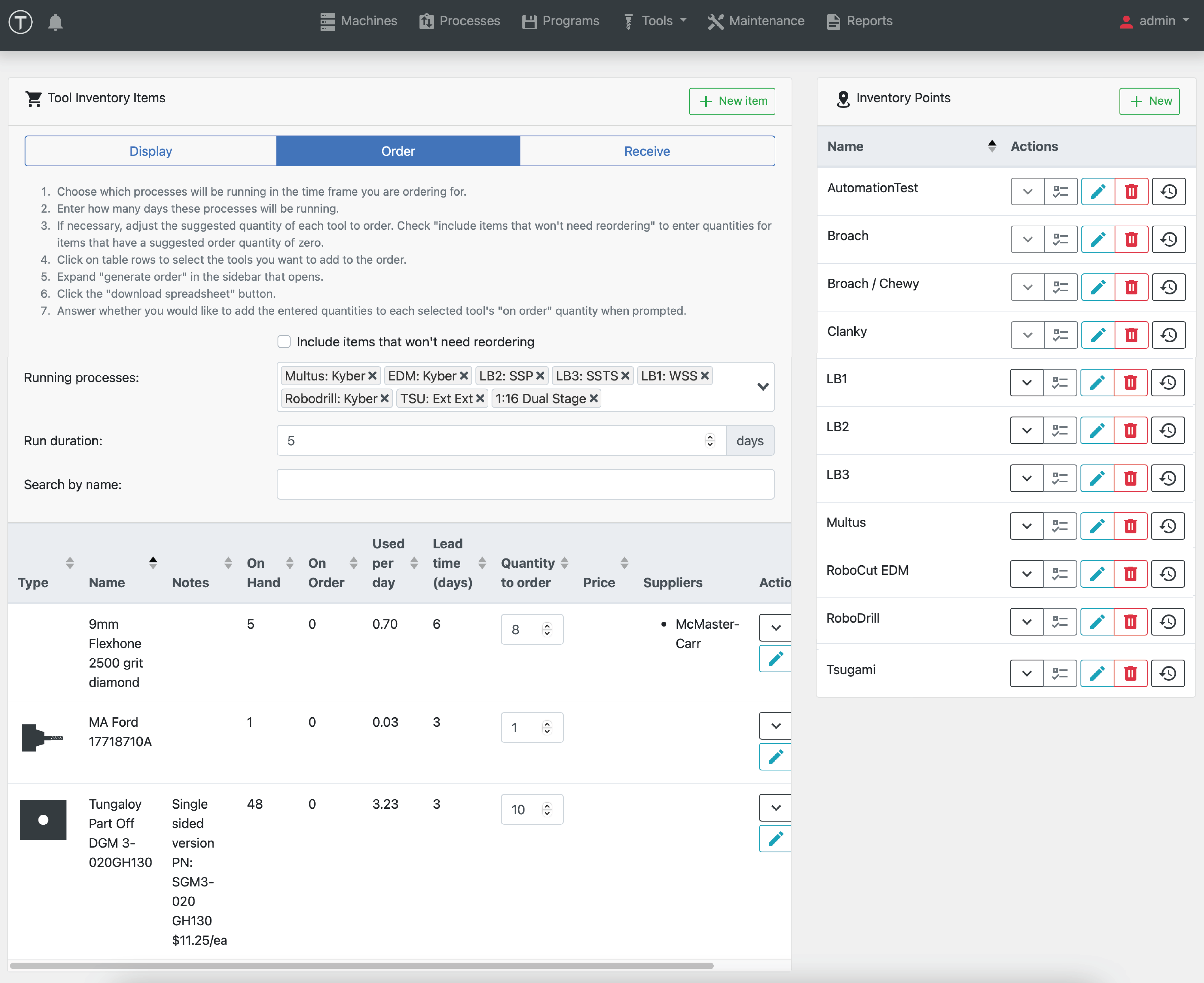

Use OnTakt to prevent a tooling stockout due to inventory function

A tooling stockout that leads to a machine stoppage is painful. Stopping a machine because an endmill or insert is out of stock can result in a several hour delay while tooling is rushed to the shop. A tooling stockout requires either an employee’s time to pick up tooling or an expedited delivery charge from a vendor. In a best case scenario tooling is on a shelf locally, but all too often a tooling stockout requires shipping, disrupting a job until midmorning the following day. OnTakt can help prevent these painful stockouts and increase run quality by allowing an operator to visualize when to order tooling to prevent these types of stockouts.

Cost Savings with OnTakt

4

HOUR STOCKOUT

$1,800

SAVINGS PER YEAR

24

MONTHS

ROI YEAR 1

8

MONTHS

ROI YEAR 2+

12

HOUR STOCKOUT

$5,400

SAVINGS PER YEAR

8

MONTHS

ROI YEAR 1

3

MONTHS

ROI YEAR 2+

PREVENT TOOLING STOCKOUTS with a smart ordering engine that signals which tools need to be on order to prevent machine stockouts due to tooling

ENABLE YOUR OPERATIONS TEAM with visibility of upcoming ordering needs to prevent painful stockouts