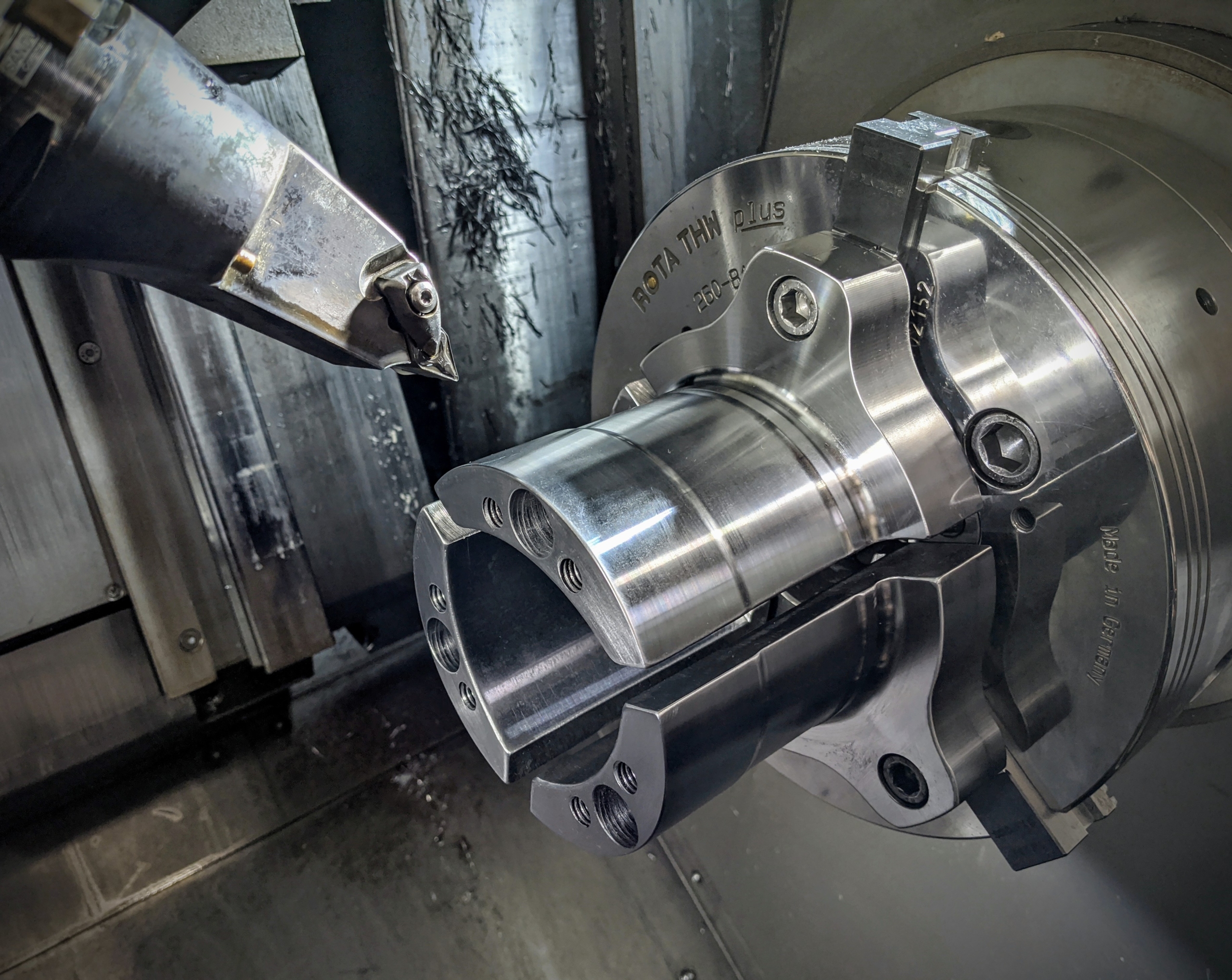

Reduce Machine Downtime

OnTakt Provides Both Preemptive and Instant Notifications Based on the Status of Machines and Tooling

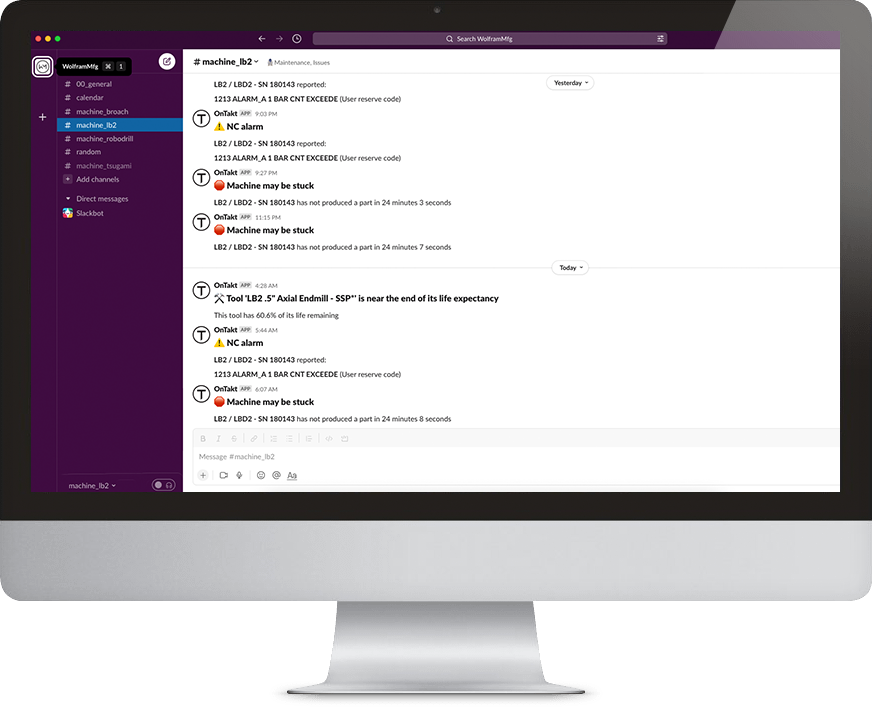

When a machine stops unexpectedly, downtime usually occurs because the operator is busy with other tasks or doesn’t know the machine has stopped. OnTakt’s integration with Microsoft Teams and Slack allows your team to receive real-time notifications of events.

With preemptive notifications, operators can plan to be available for tool changes, maintenance, and changeovers. For unexpected stoppages, an instant notification allows the team on the shop floor to quickly triage and address machines that need immediate attention. OnTakt can help to identify the issues that are affecting run quality to increase productivity and profitability.

COST SAVINGS WITH ONTAKT

10

MINUTES PER MACHINE STOPPAGE

10

STOPS PER WEEK

100

MINUTES SAVED PER WEEK

$680

SAVED PER MONTH

5.3

MONTHS

ROI YEAR 1

1.8

MONTHS

ROI YEAR 2+

RECEIVE INSTANT NOTIFICATIONS through Slack and Microsoft Teams to reduce unexpected downtime

LEVERAGE PREEMPTIVE NOTIFICATIONS to plan ahead for expected machine downtime

RECEIVE INSTANT NOTIFICATIONS through Slack and Microsoft Teams to reduce unexpected downtime