Download Data Sheets for CNC Machine Monitoring

Each product we carry monitors CNC machines for maximum uptime, production and management.

OnTakt

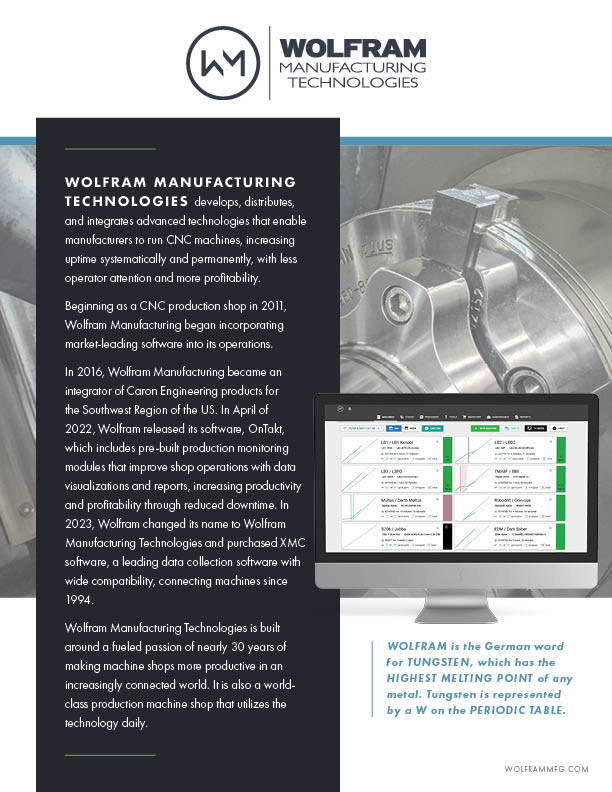

Understand your shop floor quickly and make decisions proactively. OnTakt enables machine shops of all sizes to easily leverage data to increase productivity and profitability. Every shop should be able to implement new technologies that enable simple and intuitive management of shop floor activities.

- Manage production in real time with a simple interface.

- Easily connect machines in a single dashboard.

- Capture data & visualize operations to react on the shop floor.

Download the OnTakt data sheet to learn more about monitoring your CNC machines to increase profitability and productivity of your manufacturing operations.

TMAC from Caron Engineering

Caron’s Tool Monitoring Adaptive Control (TMAC) system protects your CNC machines while providing valuable information about your cutting process. TMAC reduces the high costs associated with broken tools, lost production, and rejected parts by effectively measuring tool wear in real time. It operates on the principle that the power required to cut a part increases as the tool’s cutting edges deteriorate.

Download the TMAC brochure to learn more about Tool Monitoring and Adaptive Control for your CNC machines from Caron Engineering.

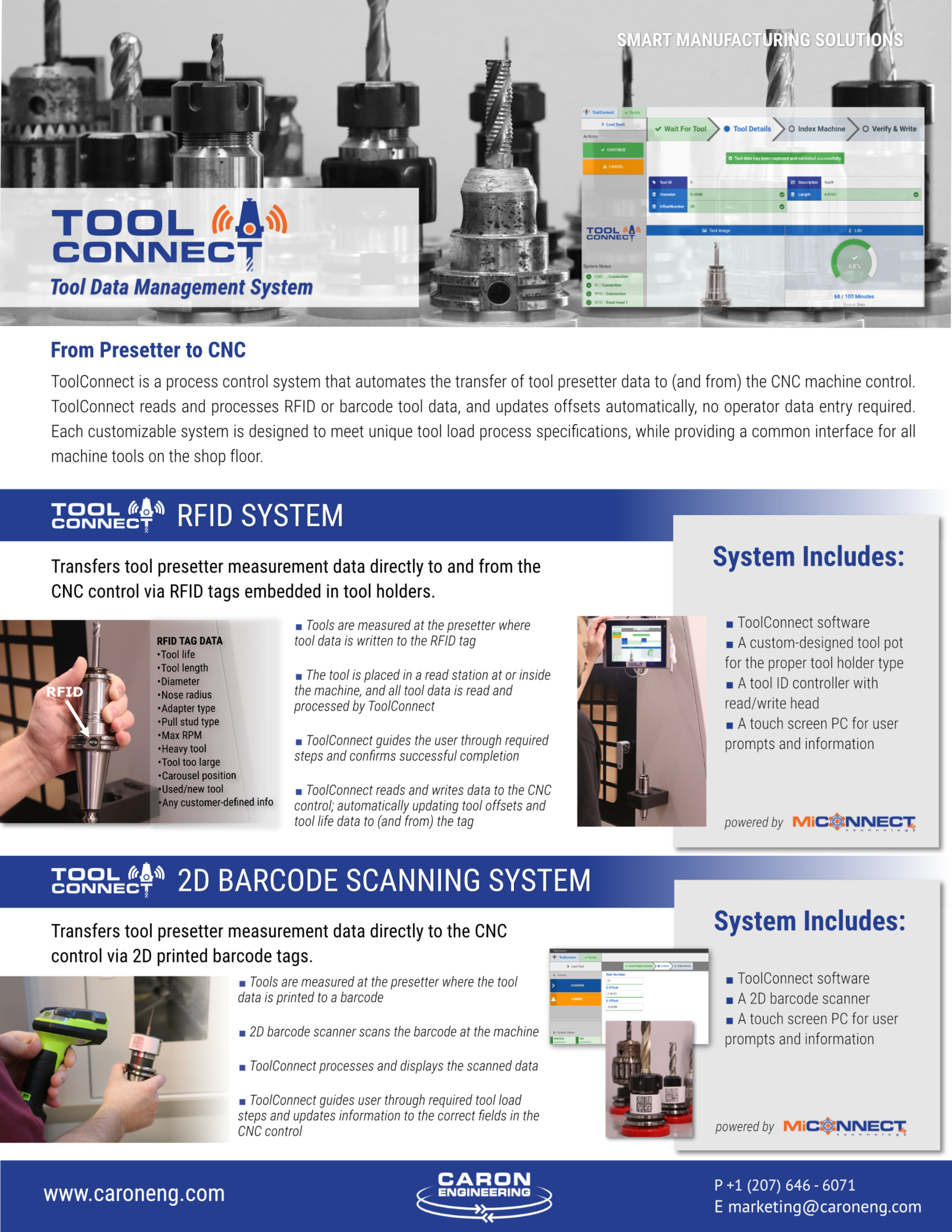

ToolConnect from Caron Engineering

ToolConnect eliminates human error and reduces setup time by automating the transfer of CNC tool presetter data to (and from) the control. Each ToolConnect system is completely customizable to meet customer requirements and tool load process specifications.

Download the ToolConnect brochure to learn more about Tool Identification and Data Management Systems for your CNC machines from Caron Engineering.

MiConnect from Caron Engineering

MiConnect technology is a flexible and customizable application builder for the CNC machine manufacturing environment. It is used to connect devices and operations on a shop floor, automate and simplify CNC manufacturing processes and guide operator flow, to optimize productivity.

AutoComp from Caron Engineering

Manually entering tool wear offsets after part measurement is time consuming and susceptible to operator error. Mistakes calculating offsets or incorrectly inputting data can result in scrapped parts or machine damage.

Download the AutoComp brochure to learn more about Error-Free Tool Offset Control for your CNC machine from Caron Engineering.

DTect-IT from Caron Engineering

DTect-IT is a powerful solution for monitoring the health of your CNC machine. Using high precision sensors for vibration, strain, power, and analog (to connect any sensor with a 0 to ± 10 VDC analog signal), the user can monitor machining conditions using the advanced software analysis options.

Download the DTect-IT data sheet to learn more about CNC Machine Condition Monitoring Systems from Caron Engineering.

SmartLight from Caron Engineering

More Than Just a Status Light. Caron Engineering’s (CEI) Smart Light System Controller and configuration software is compatible with all Fast Process Data (Balluff) Smart Lights. With easy to use, colorful screens, the user can preconfigure recipes for basic light outputs, or use direct set protocol for advanced control of the light stack to dynamically change the light.

Download the data sheet to learn more about how to enable your operators to know more about what your CNC machines are doing with SmartLight from Caron Engineering.

CNC Machining with Wolfram Manufacturing

Wolfram is not your average contract manufacturer! We help our customers build complete, robust manufacturing processes that enable them to grow and scale their businesses. We leverage advanced technologies to optimize our CNC’s that enable us to run lights out production with minimal operator intervention.

Download the brochure to learn more about how CNC Machining with Wolfram Manufacturing can help make your business more successful.