Technology at Wolfram

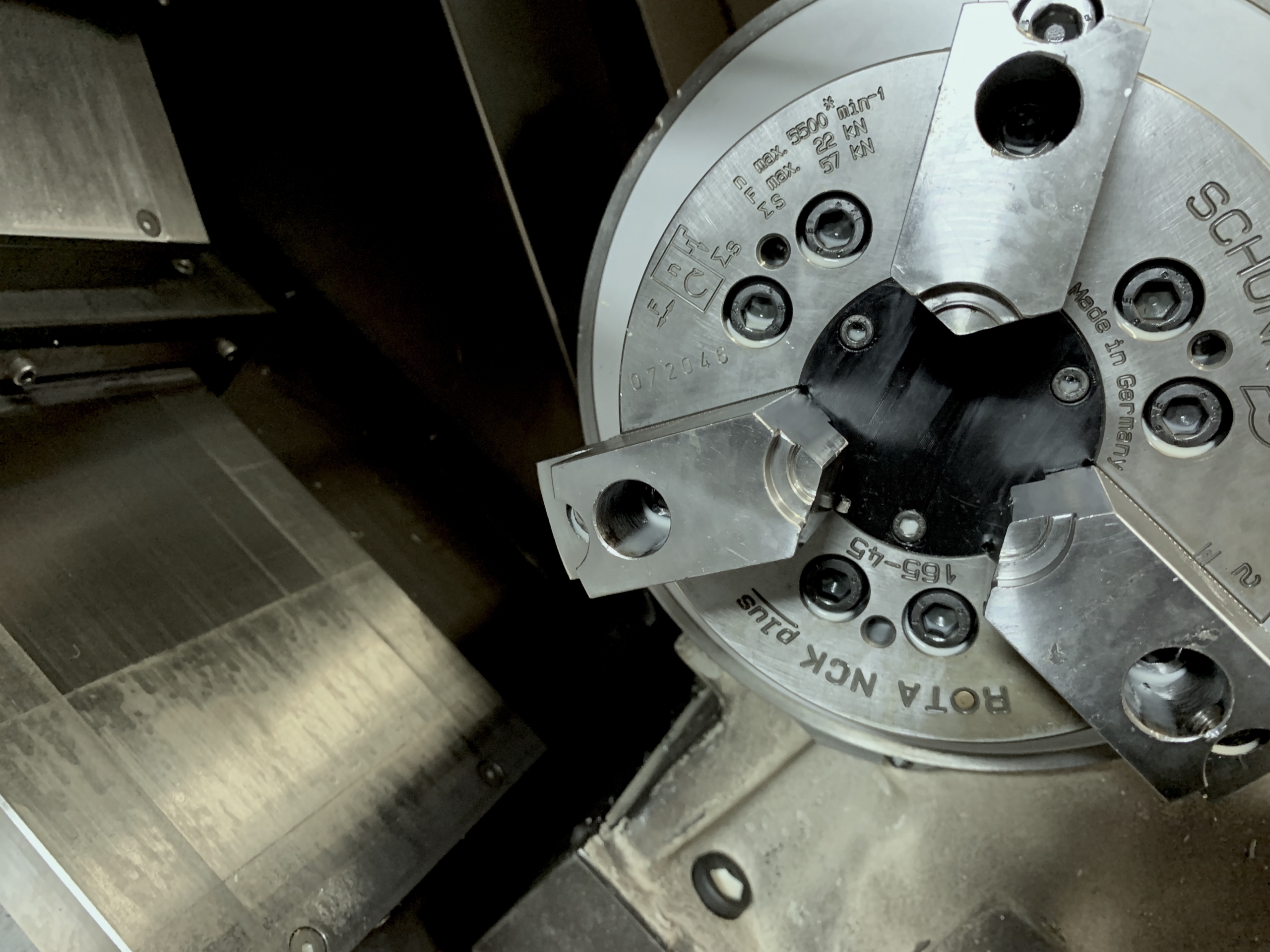

Single Piece Flow and Single Setup Machining are overarching goals in process design through machining, inspection, and deburr. This approach naturally optimizes personnel and equipment for throughput.

Listed below are technologies and processes honed in our internal manufacturing operations.

Programming and Simulation

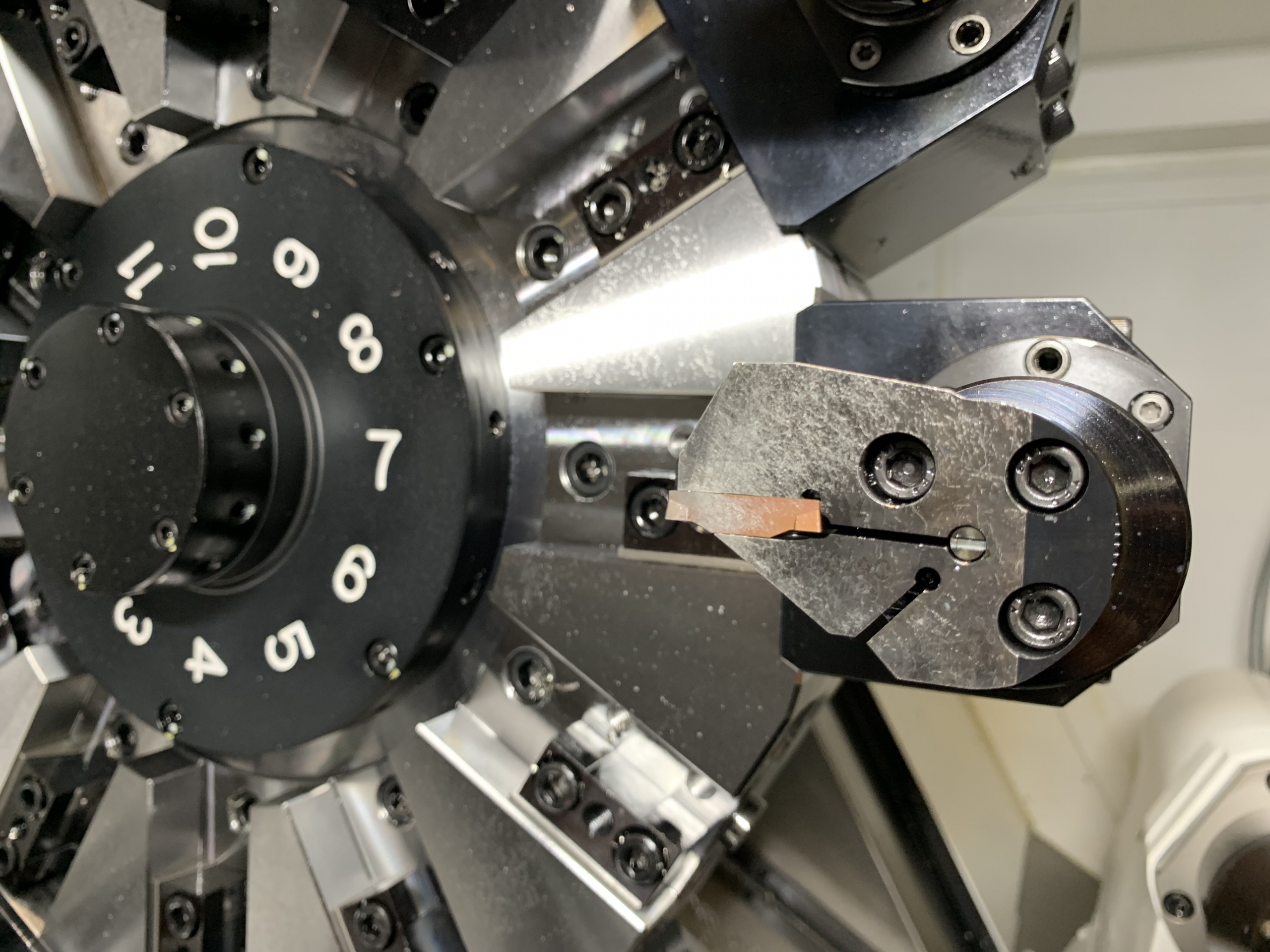

- Modern tool strategy

- Modern machine strategy

- Full simulation of machine, setup, and tooling

- 3D printed full size plastic part for inspection and machine setup

- Optimized toolpaths via specialized software

- Deburr machine paths

- EDM reduction

- Gundrill reduction

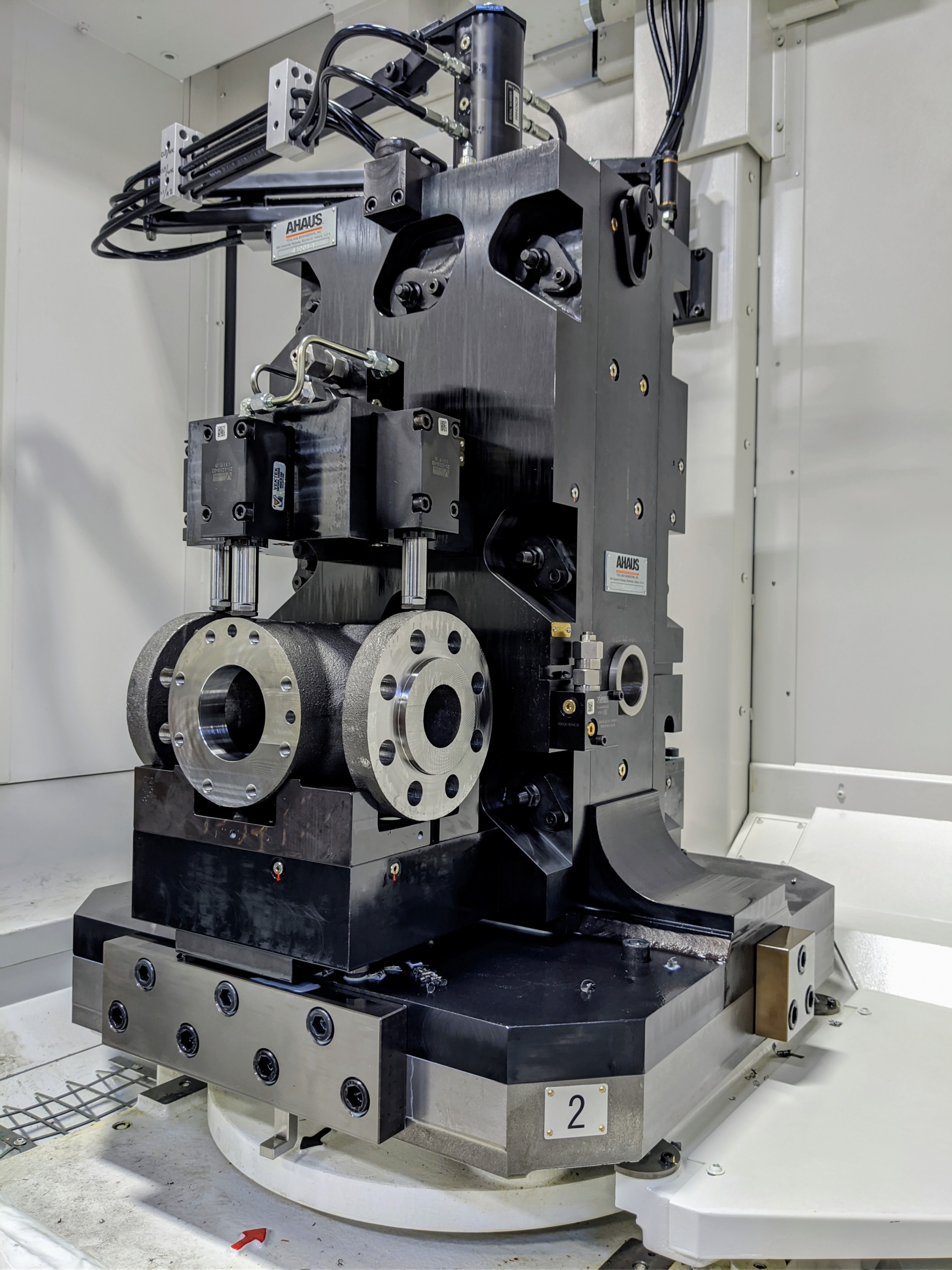

- Work holding design

Lean

- “Poke a yoke” – Error resistant process by design

- “Visual Management” – Tools to assist keeping a process under control with simple visual cues

- “Takt Board” creation

- “Standard Work” – Documentation standards for defining a repeatable process

- “SMED Planning” (Single Minute Exchange of Dies) – Process for thoughtfully making setup and part exchange as fast, tool-less, and repeatable