XMC®

Complex application and software solutions for the world’s most demanding industries.

We help manufacturers in highly regulated industries solve the most complex challenges by providing transparency and precision through connected plant software systems, motion-controlled machines and CNC machine tools. XMC® is a universal machine communication platform that rapidly connects SCADA, HMI, manufacturing intelligence and custom apps to diverse shop floor machines and devices.

Better Operations Thru Better Insight

- Measure and visualize real-time machine utilization and performance

- Automated time study analyzer tracks part cycle times

- Monitor machine and/or spindle health indicators for preventive maintenance

- Receive proactive notifications of events that may lead to unplanned machine downtime

- View and analyze metrics for lean and continuous improvement initiatives

Business Benefits

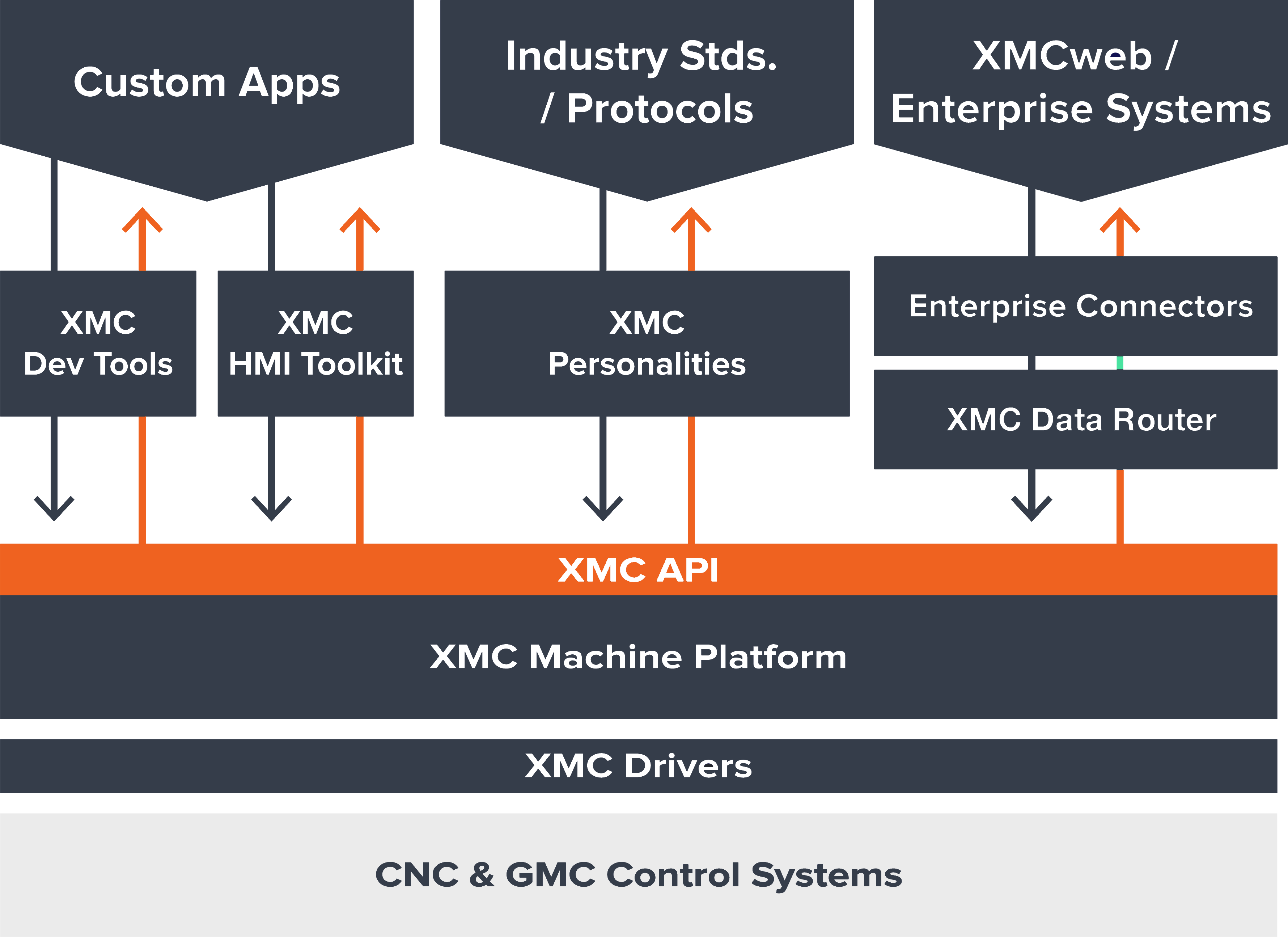

- Universal machine communications platform for 3rd party, custom and XMC solutions

- One programming model lowers the learning curve

- Patented technology communicates with many types of machine controls

- 100% software with no proprietary hardware wired to machines

- Configurable to exact customer needs

Technical Benefits

- API-based, read/write capability, designed for performance

- 35+ software drivers for different CNCs/motion controllers

- SDK to extend for industry standards, popular protocols or proprietary interfaces

Leverage the power of XMC® to put your data to work.

Raw data enters the XMC® platform through the machine tool, plus any barcode readers, sensors, or other sources you may utilize. Usually, no additional hardware is required.

Event-based data flows to multiple upstream systems (including XMCweb®) through the XMC®datarouter, creating common event data from machine-specific data sources.

XMCweb® analyzes and visualizes your data and presents it in useful, easily digestible formats that include machine/spindle utilization, overall equipment effectiveness (OEE), part cycle times, takt times, and machine alarm history

Receive automated email and/or text notifications based on machine conditions